Indentifying water reuse systems in the microelectronics industry can be a challenge. Contributing factors include: varying composition of numerous wastewater streams and having multiple locations where recovered water could be reintroducted into the facility. There are several strategies for selecting waste streams and their re-introduction points after treatment. The correct strategy for your facility is determined based on concertration levels of impurities and water reuse goals.

Water Reuse Objectives

Waste streams with the lowest concentration of impurities would be best suited for reuse into an ultrapure water (UPW) system. While waste streams with the highest concentration would best be suited for non-contact applications such as cooling towers and abatement scrubbers. Another consideration for microelectronics manufacturers are the objectives for water reuse. Objectives may include reducing city water intake at current production levels, maintaining water intake while expanding production or simply reducing liquid discharge from the facility.

When using existing wastewater treatment processes, residual contaminants need to be reduced to acceptable levels, dictated by the re-introduction point water quality criteria.

Technologies used in Water Reuse Systems:

- Highly efficient filtration systems

- Minimize backwash waste

- Reduce water consumption and save energy

- Minimize maintenance requirements

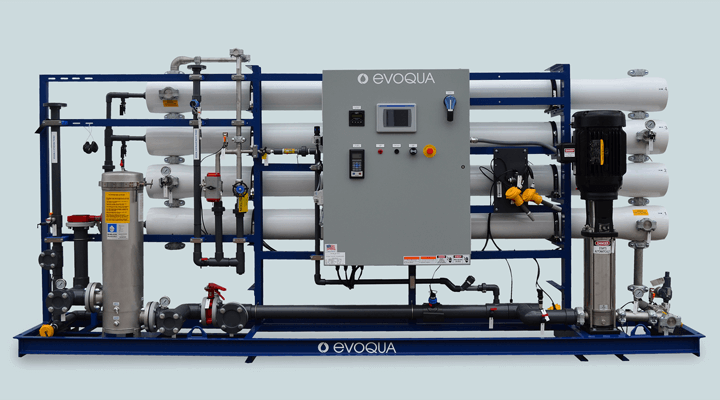

- Reverse osmosis systems

- Reduce anions, metals, silica, etc.

- Semi-permeable membrane used to remove solids

- Conventional UV or advanced oxidation process (AOP)

- TOC reduction

- Effectively inactivate a range of microorganisms

- Water reuse capabilities to meet overall sustainability goals

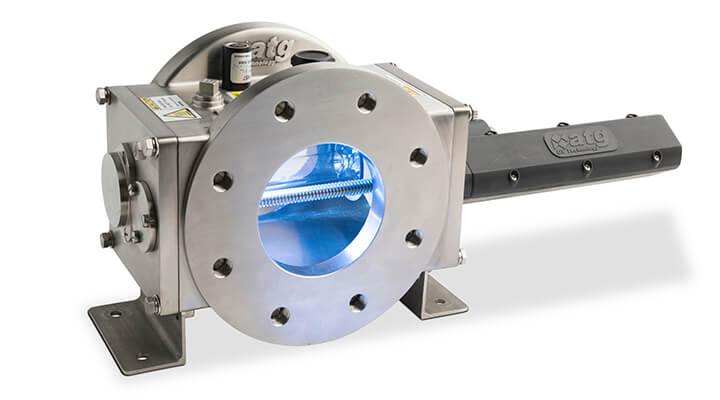

In addition to treatment equipment, flow equalization tanks, fast on-line analytical instrumentation and automated divert valves are common for risk minimization.