Design Challenge

A hydrogen production company in the western U.S., was directed by the local municipality, under a drought-driven water savings program, to reduce feedwater demand from the local supply. The company was still obligated to produce the same volume of high purity water for process use as well as to provide treated water to a neighboring hydrocarbon production facility for steam use. Evoqua was the existing water services provider, having designed, manufactured, installed and operated a water treatment system to produce high-purity water under a long-term build-own-operate (BOO) agreement for several years.

The system included media filtration, a softening process to remove excess hardness, chemical supply for pH control and chlorine reduction, a reverse osmosis (RO) process to remove the bulk of dissolved ions and final off-site regenerable ion exchange service equipment.

The system had originally been efficiently designed at 80% overall recovery, producing 1,300 gallons per minute of treated water with a feed flow of 1,625 gallons per minute. The challenge was to reduce the feedwater demand by 10% to meet the municipality’s regulation without impacting overall production.

Economic Challenge

In a BOO agreement, equipment, maintenance and consumables are included in a monthly fixed price. Chemicals are also provided, and priced based on a variable billing structure. The chemical spend is then dictated by volume produced and remains fixed on a volume basis (typically $ per 1,000 gallons produced).

The company preferred to minimize any costs to upgrade the system to meet the regulatory requirements. The challenge was to produce more water while keeping additional equipment and operating costs to a minimum.

Solution and Results

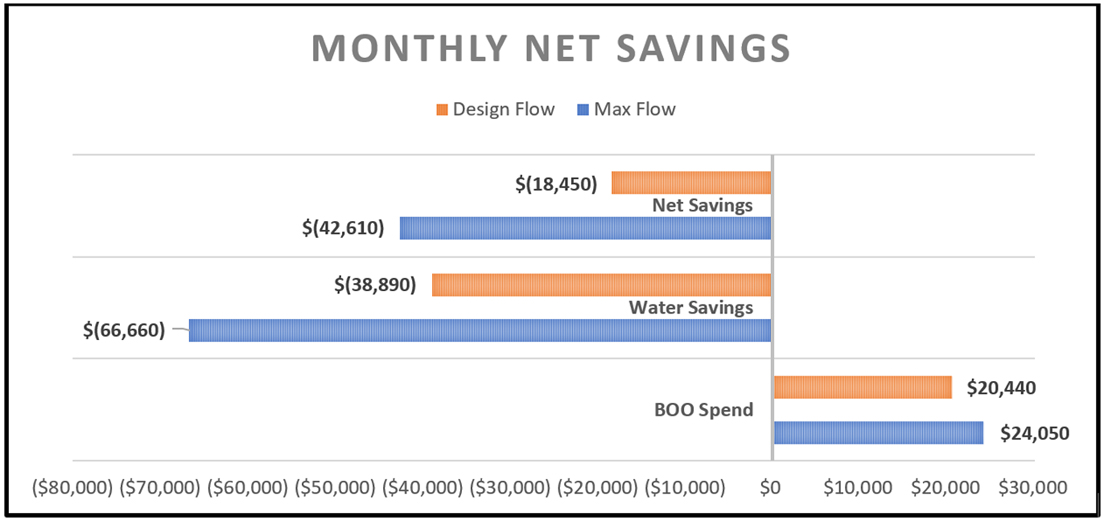

Evoqua’s design philosophy is based on a holistic approach, considering customer needs and desires, space limitations and life-cycle costs. Evoqua engineered the upgrades to achieve the 10% reduction in feedwater demand while also reducing wastewater, allowing for treatment and reuse of a portion of the waste to supplement the feedwater flowrate. To accomplish this, Evoqua added a brine recovery reverse osmosis (BRRO) system to treat the waste stream of the primary RO system. By processing the primary RO waste through a BRRO, Evoqua was able to recover 50% of the waste stream, which represented as much as ~85M gallons of wastewater reduction per year while reducing the feedwater demand by the same amount. A further benefit of the process was that the product water from the BRRO was of higher quality than the municipal supply. By reintroducing this water to the front of the system, the feedwater to the primary RO improved, improving overall operation and reducing final ion exchange (IX) requirements. Design value benefits to the customer are defined below.

Operational Benefits:

- Allows staff to focus on core competencies.

- Quality and quantity guarantee over length of contract.

- Make-right protection.

- Partnering. Evoqua has the "skin in the game" to operate efficiently.

- Minimized downtime.

The customer financial structure and policies presented additional challenges. While they were required to meet the new regulatory requirement, they remained under pressure to preserve capital. To meet these needs, Evoqua incorporated the cost of additional equipment and services into the existing BOO contract. Furthermore, the new design resulted in a 10% reduction in feed water costs and a 50% reduction in wastewater disposal costs. Economic benefits of a BOO agreement to the customer are defined below.

Financial Benefits:

- Capital conservation. No up-front capital expenditure.

- Desire an operating lease. This requires that assets be skid mounted and reusable.

- Long-term steady spend stream. Predictable. No surprises.

- Ability to exit contract at any point, subject to a cancellation charge to cover Evoqua's sunk cost.

- Design/build financial risks eliminated.

- Minimized downtime.

The cost to purchase and dispose of water was not insignificant. The final price to the customer was more than off-set by the reduction in feedwater supply and wastewater disposal costs the customer paid the municipality. In this scenario, Evoqua was able to provide a solution that met the regulatory requirements, while reduced the customer’s overall spend.

To meet all requirements, Evoqua performs periodic business reviews with the customer to review safety, system data, confirm long-term goals are “on-track”, schedule maintenance activities and maintain the business partnership.