Located between Milwaukee and Madison at the intersection of two Wisconsin interstates, the Village of Johnson Creek is one of the fastest growing communities in the region. It bills itself as the "Crossroads with A Future." Recently, the town had to step up planning for the future as its wastewater treatment plant reached a crossroads of its own.

Challenge

The wastewater treatment system, treating an average of 0.35 MGD, was reaching the end of its useful life, with its five Rotating Biological Reactors beginning to require added maintenance. With the Village of Johnson Creek Water Utility (VJCWU) operating entirely on ratepayer revenues, a solution was needed that would allow for sustainable growth while meeting strict budget requirements.

Solution

For planning assistance, the town turned to an engineering firm in Wisconsin to help evaluate advanced nutrient removal technologies capable of meeting stringent effluent limits. The engineering firm presented a variety of approaches, including systems based on both single-stage nitrification and simultaneous nitrification/denitrification (SND), the driving technology behind the Orbal® system from Evoqua. Based on its proven performance, energy efficiency, reliability, and more than 800 successful installations worldwide, the Orbal system was selected for the project.

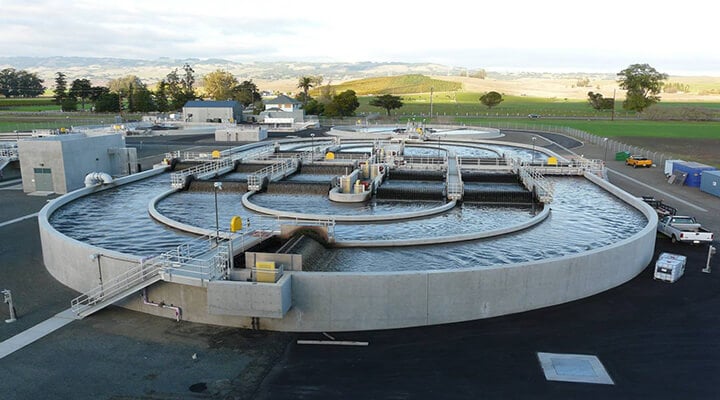

The Orbal system was designed for an average flow of 0.5 million gallons per day (MGD) with a peak flow of 1.1 MGD. The 3-channel basin, concentric ring design features Evoqua's OX™ disc aerators to facilitate efficient oxygen transfer and mixing efficiency and reduce energy consumption.

In the VJCWU implementation, the Orbal system is preceded by an anaerobic digestion system for high-performance biological phosphorus removal. The system also includes flat weatherhoods to reduce splashing, protect the disc aerators, and provide easy access to components for maintenance.

How the Orbal® System Works

The Orbal system’s suspended growth activated sludge process begins when screened and de-gritted wastewater is directed to the anaerobic selector basin and mixed with RAS from the clarifiers to form the system’s mixed liquor. The anaerobic selector basin helps to promote growth of phosphorus absorbing organisms (PAOs) with phosphorus release occurring in this basin.

The combined mixed liquor passes progressively through the Orbal system’s channels before passing on to the final clarifiers. The outer channel is operated as an aerated anoxic reactor with dissolved oxygen levels near 0 mg/L. Simultaneous nitrification/denitrification release occurs in this zone. Oxidation/reduction potential (ORP) is used to monitor the condition of the outer channel. The middle channel is a transition zone between the outer anoxic channel and the inner aerobic channel. Its condition may vary depending on the load coming into the plant. The inner channel is maintained in an aerobic state with dissolved oxygen levels at or above 2.0 mg/L. This supports the final nitrification required to complete treatment. Channels are physically separated so the environment within each channel can be controlled precisely to produce consistent treatment results.

Results

Since system startup in 2018, the Village of Johnson Creek Wastewater Treatment plant has consistently performed well within discharge permit limits. Effluent ammonia is consistently 0.2 mg/L against a limit of 20 mg/L and phosphorous is consistently 0.2 mg/L against a limit of 1.0 mg/L, without tertiary filtration or the need to add chemicals.

Plant operations personnel are pleased with the reliability of the Orbal® System and the ease of routine maintenance, and the Village of Johnson Creek can now be assured that they are prepared for the future.