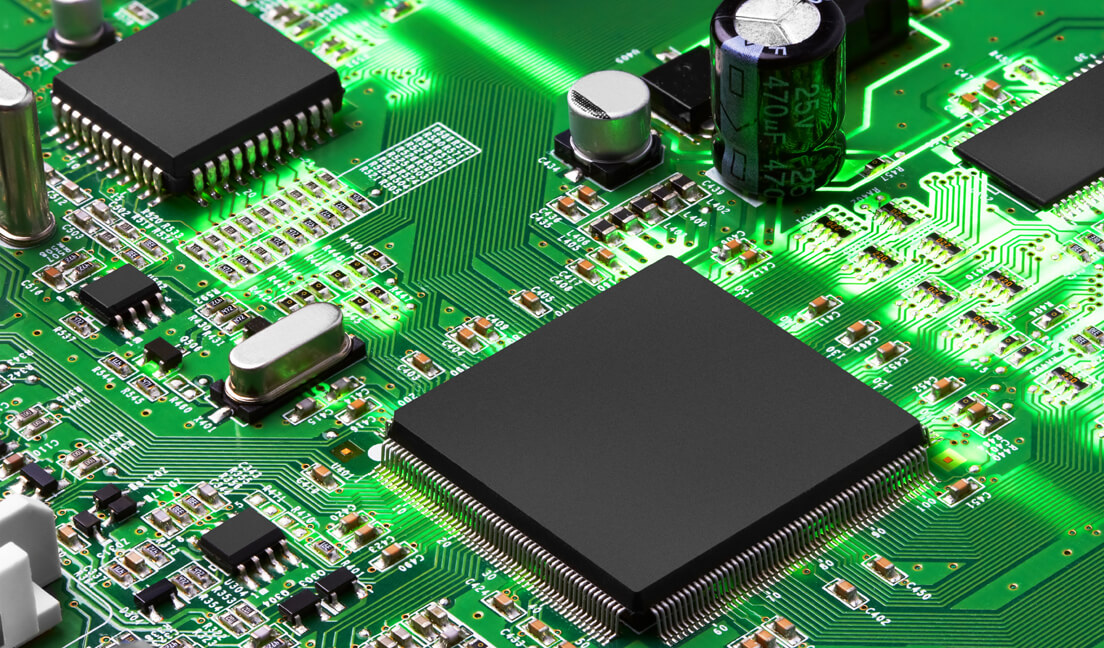

Printed Circuit Board (PCB) manufacturing and populating are processes that require both pure water and wastewater treatment. High purity deionized (DI) water is crucial in removing environmental cantaminants, solder, or other impurities from circuit boards. This allows PCB manufacturers to process the highest quality product without damaging any components. In addition to high purity DI water, wastewater left from the circuit board manufacturing process also requires treatment. Spent process and wash waters can contain metals waste (Ni, Cu, Ag, Au, Pb, Sn) as well as other unwanted contaminants (pH, TOC, TDS) which must be treated prior to discharge or recycle.

Printed circuit board manufacturers require water treatment for both manufacturing and treatment of wastewater

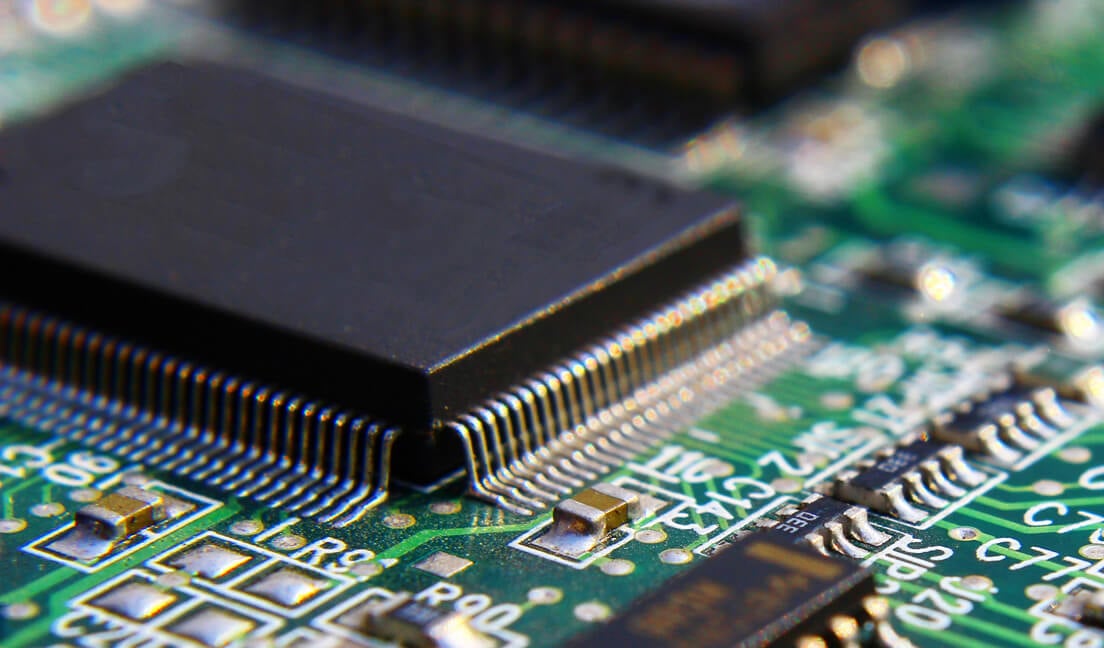

Treatment Solutions for Printed Circuit Board Manufacturers

Evoqua supplies services and equipment to supply high purity deionized water for rinse water and process wash water makeup. Our wastewater ion exchange systems and capital equipment are used to remove the hazardous components, allowing the treated rinse water to either be recycled back to the washers or discharged to the POTW. The contaminant-laden ion exchange media is shipped back to Evoqua’s owned and operated RCRA treatment facility for compliant processing which epitomizes the “cradle to grave” waste treatment approach.