Challenge

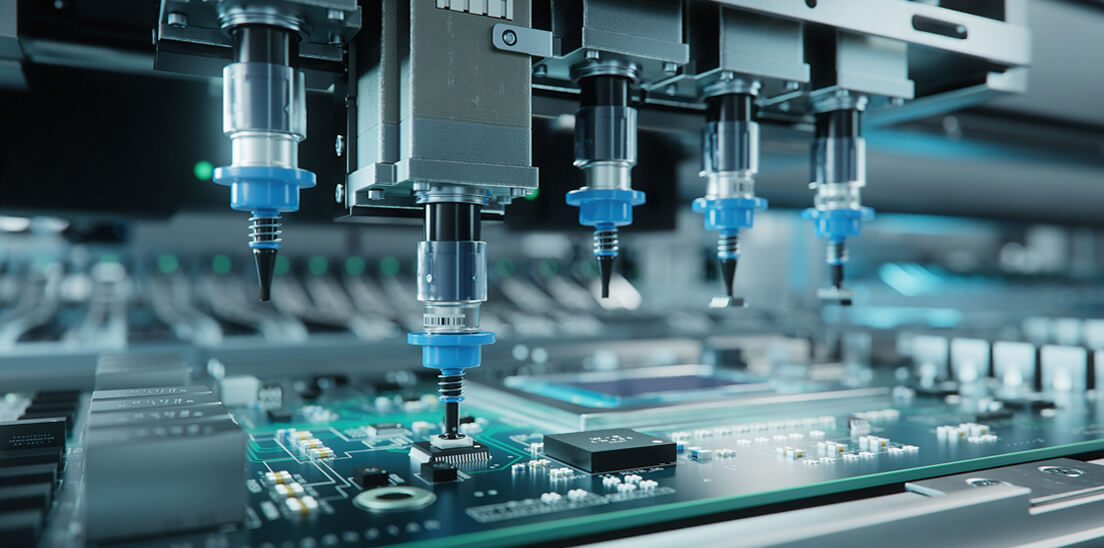

A Southeast manufacturer of printed circuit boards for the defense and medical industries was experiencing poor and inconsistent water quality on their board washing process, which utilized a deionization (DI) system from a local water treatment company. The water quality issue was resulting in re-work of off-spec boards, additional labor to re-process boards that failed quality control review, and higher costs overall. As the current supplier was unable to help them identify and resolve the issue, the customer reached out to Evoqua to assist them in improving the quality of their washing process.

Solution

Evoqua sales engineers performed a site audit of the customer’s manufacturing process, reviewed the board washing operation and obtained a sample of the unknown contaminants that were building up on the surface of the rinse tank. The customer believed the contaminants were biological in nature due to the high level of organics present from the required cleaning chemistry. However, Evoqua’s treatability and analytical testing of the material at our Roseville, MN laboratory determined that these contaminants were in fact inorganic - likely resulting from incomplete removal of dissolved solids by the existing supplier’s DI system.

As a result, Evoqua recommended a Wastewater Ion Exchange (WWIX) system consisting of 10 micron prefiltration, 3.6ft3 FRP vessel with specialized coconut carbon effective at reducing board washing cleaners, 2 x 3.6ft3 Mixed Bed Type 1 resins, and 10 micron post-filtration to provide a high level of total dissolved solids removal at a flow range of 2-10 gpm.

As Evoqua’s WWIX system is a service-based solution, the customer was able to replace their existing supplier’s DI system with the new WWIX equipment within 2 weeks of placing the order.

Results

Following the installation of the WWIX system, the contaminant build-up in the rinse tank improved markedly. In addition, the customer was able to consistently meet their 1 meg Ohm quality goal in the recycled water and reduce the level of organics that were introduced by their cleaning process. These improvements in the recycled water quality have resulted in lower operating expenses by reducing the number of off-spec boards that require additional labor to reprocess.

By relying on Evoqua’s WWIX laboratory services and experience with the water requirements necessary for successfully recycling water from electronic board washing processes, the customer was able to improve the efficiency of their operation, reduce costs, and focus on delivering high-quality electronics for their critical defense and medical customers.