Challenge

At a Midwest printed circuits manufacturer, achieving optimal water treatment efficiency became a critical concern. The 80,000 square foot facility faced the constant challenge of promptly detecting disruptions in their treatment processes, while also striving to streamline operations, reduce costs, and maintain high product quality.

Conventional systems often struggled to meet these demands, resulting in productivity and financial consequences. Moreover, the business encountered hurdles in their efforts to optimize operations, control expenses, and uphold stringent product quality standards. To address these pressing challenges, they were looking for an innovative solution that could deliver real-time data and accurate quality information.

Solution

Evoqua’s team of wastewater experts evaluated the application and determined that it was a good fit for Water One® WX Services. This smart wastewater recycling system combines wastewater ion exchange (WWIX) technology with digital enablement, remote monitoring and predictive analytics to ensure recovered water quality always meets specifications.

This particular application was for the final rinse in printed circuit board manufacturing, which requires the removal of lead, total dissolved solids (TDS) and other non-hazardous materials. Evoqua provided four 3.6 cubic foot tanks with a flow of 8 gallons per minute. The tanks were connected to an advanced control panel with digital monitoring capabilities (see picture below).

Key performance data is monitored 24/7 via a cellular connection and Evoqua’s Link2Site® remote monitoring technology, which sends alerts for leaks, tank effluent quality, flow restrictions and tank exchanges. Evoqua’s AQUA pro service team quickly addresses alerts or schedules tank exchanges to keep the system operating at peak performance.

Water One WX services predictive algorithm and remote monitoring capabilities also provides data-enabled insights to proactively identify and resolve water quality issues before they impact production. Access to data reports can also provide the facility with a better understanding of their water quality, water usage, and system performance over time.

Results

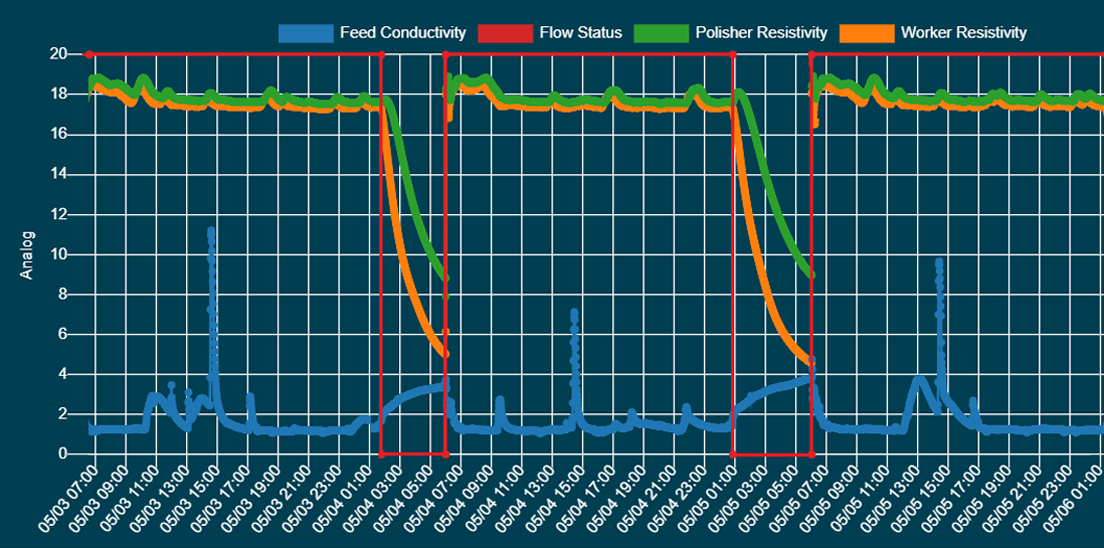

With a comprehensive view of water quality in real-time, site operators were able to make data-driven decisions to optimize the treatment process. The data in the chart below shows a brief spike in feedwater conductivity every day between 2:30 PM and 3:00 PM. This indicates a contamination issue and upon further investigation, it was identified as the beginning of a shift where input water quality was dramatically affected by the addition of cleaning chemicals to the tooling.

Water One WX Service Feedwater and Effluent Quality Chart

The implementation of Water One WX Services provided the data needed to help the customer identify this process disruption and determine the potential process improvement. To optimize system performance, changes were made to their standard operating procedures, adding chemicals periodically throughout the shift, rather than all at one time. The difference in production quality was immediate, showing a full percentage point decrease in rejected parts (100/10,000 improvement) and improved throughput in the process tool.

Water One WX Services also allowed the customer to predict the need more accurately for ion exchange vessel swaps. The system analyzes remaining estimated throughput, allowing maintenance personnel a better window into planned, future work. This provides full asset utilization and ensures the facility has the water quality they need to meet production requirements.

The implementation of a turnkey, digitally enabled, wastewater recycling system empowered the business to establish a more streamlined process and minimize resource wastage, resulting in cost reduction and improved operational efficiency.

Maximize Your Productivity and Product Quality with Water One® WX Services

Experience the benefits of real-time quality tracking, data-enabled insights, optimized processes, and enhanced product quality, positioning your industrial facility for sustainable success in the competitive landscape. Contact us today to discuss your application.

Contact Us