Ostara's Pearl® System by Evoqua

See All Digestor ComponentsEnhance Biological Nutrient Removal and recover nutrients for transformation into an eco-friendly phosphorus fertilizer.

- is the minimum order quantity for this product. Please check quantity and add to cart again.

- View Gallery

Enhance Biological Nutrient Removal and recover nutrients for transformation into an eco-friendly phosphorus fertilizer.

Description

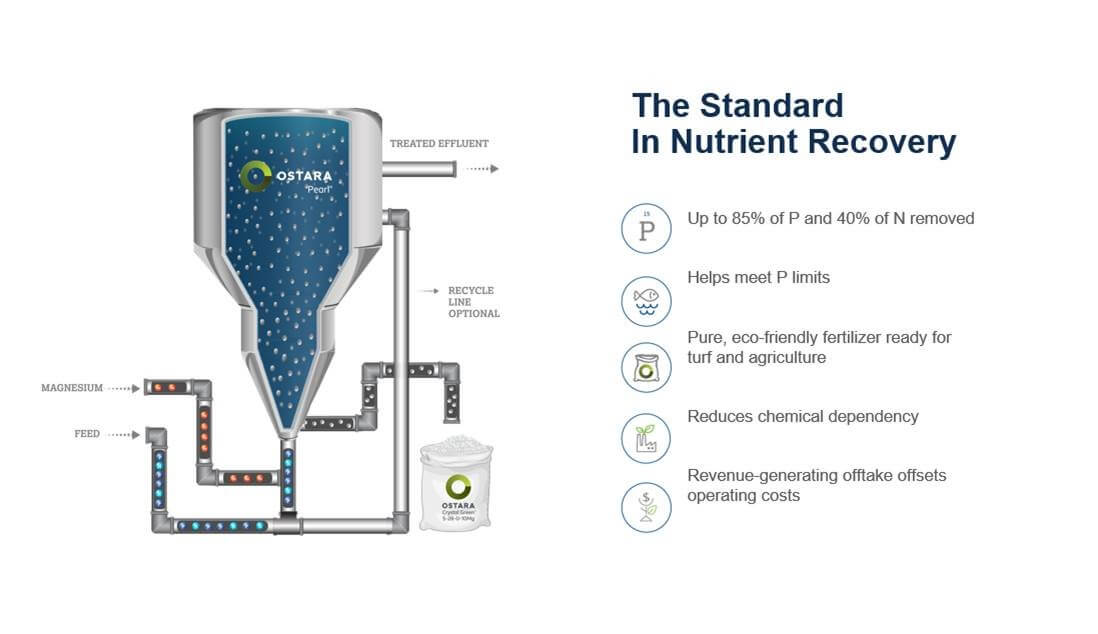

Ostara’s Pearl® system from Evoqua Water Technologies is a fluidized bed reactor that harvests nutrients from wastewater and transforms them into an eco-friendly fertilizer. This cost-effective nutrient recovery solution converts wastewater treatment plants into true resource recovery facilities helping create a circular economy.

The Pearl system is designed to recover phosphorus from pre-and post-digestion liquors, as well as industrial streams, through the controlled precipitation of crystalline struvite. Within the Pearl system reactor, the growth of struvite (magnesium ammonium phosphate) is facilitated by the addition of magnesium in a controlled pH setting. This allows nutrients to crystallize into eco-friendly fertilizer granules, which are harvested, dried and then distributed and sold by Ostara as Crystal Green® Fertilizer. The treated effluent is then discharged from the top of the reactor and returned to the plant with significantly reduced nutrient content.

Complementing the Pearl system is the WASSTRIP™ system designed to remove internal phosphorus providing critical benefits to plant operations, turbo-charging nutrient removal and recovery in a controlled environment. The process tackles struvite issues, improves dewaterability and reduces biosolids production.

A Modular Phosphorus Recovery Solution

Introducing Ostara’s Pearl® FX system from Evoqua, a cost-effective modular nutrient recovery solution ideal for treatment plants that are from 5–30 million gallons per day (MGD) in size. The Pearl FX system is pre-engineered and pre-assembled package plant solution allowing for simpler and faster installation requiring less physical space and site preparation resulting lower installation cost and maintenance.

Crystal Green, Pearl, and WASSTRIP are trademarks licensed by or through Ostara Nutrient Recovery Technologies Inc.

Optimize Plant Operations and Achieve Cost Savings

Operating Benefits

- Reduce phosphorus recycle

- Reduce struvite maintenance costs

- Mitigate digester struvite buildup

- Improve dewaterability

- Reduce polymer demand

- Reduce sludge production

Economic Benefits

- Commercial fertilizer production

- Guaranteed fertilizer buyer and revenue

- Reduced chemical purchase costs

- Reduced sludge disposal costs

Environmental Footprint

- Full cycle resource recovery

- Reduce carbon footprint

- Reduce chemical demand

Documentation

Ostara Pearl System Case Studies

Case Study – Energy & Nutrient Recovery Factory

The Dutch Water Board Vallei en Veluwe have transformed Amersfoort WWTP into an "energy and nutrient factory"

Case StudyCase Study – Stickney Water Reclamation Plant

The World’s Largest Nutrient Recovery Facility

Case StudyCase Study – Saskatoon Wastewater Treatment Plant

Nutrient Recovery with WASSTRIP® Process Restores Saskatoon Plant’s Efficiency

Case Study