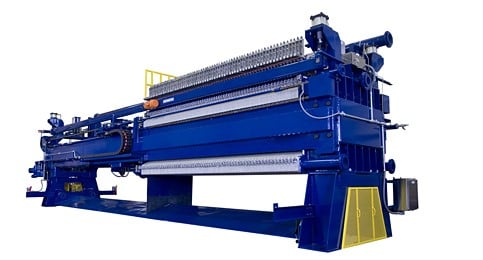

MCPress® Filter Press

See All Filter PressesVersatile dewatering device ideal for larger throughput which can withstand the harshest of environments.

- is the minimum order quantity for this product. Please check quantity and add to cart again.

- Improved Uptime, Efficiency and Costs

- The driest cake — minimizes handling and processing costs

- The clearest liquid effluent — suitable for reuse, improves water conservation

- Durable robust design and construction — minimizes maintenance costs

- View Gallery

Versatile dewatering device ideal for larger throughput which can withstand the harshest of environments.

- Improved Uptime, Efficiency and Costs

- The driest cake — minimizes handling and processing costs

- The clearest liquid effluent — suitable for reuse, improves water conservation

- Durable robust design and construction — minimizes maintenance costs

Description

The MC Press® Filter Press from Evoqua is one of the most versatile dewatering devices for use in high solids filtration applications which is designed and manufactured under the strictest ISO 9011:2008 quality management system. With unique design features and a simplified operation, it can achieve the driest filter cakes with or without diaphragm squeeze. The MC Press® filter press provides high cake discharge consistency, low cake moisture content and superior reliability coupled with greatly reduced maintenance requirements.

The MC Press® filter press is utilized in the mining industry to process tailings and mineral concentrates in every environment, including the most rugged environments at the highest, driest altitudes.

The MC Press® filter press is also idealy suited for large industrial dewatering applications such as Chemical processing and Wastewater

Features & Models

Features

- Cloth Wash System

Feature: All cloths can be washed after every cake discharge cycle - or as frequently as is needed.

Advantage: Extends cloth life and improves press operation by cleaning the sealing surfaces between plates preventing production losses. - Cake Discharge Monitoring System (Optional)

Feature: Photoelectric beam checks to determine that all cloths are in raised position when press is fully open.

Advantage: Insures that all cakes have discharged from the press before proceeding with the next cycle. - Plate Travel Assembly (S & D Models)

Feature: The press is opened and closed by a simple mechanical drive system that is easy to understand and maintain.

Advantage: Reduced maintenance costs. No special tools or specialized maintenance training required. - Spring-Supported Cloth Bars

Feature: Cloths move down as cakes are discharged. Cakes shear from cloths when cloth support bars reach the end of their travel.

Advantage: 2-minute cloth changeout. Proven to be the most reliable method of filter cake discharge.

- Vibration Bars

Feature: Act as a backup to the primary cake discharge system. Activated when cake discharge monitoring system detects that one or more cakes have not discharged.

Advantage: Assists with filter cake discharge if process conditions change and cakes become sticky. - Linked Filter Plates

Feature: The dewatered filter cakes are quickly discharged as the press opens.

Advantage: Shorter cycle times and greater throughput. - Press Frame

Feature: Can be provided with capacity for additional filter plates.

Advantage: Press can be easily upgraded at minimal cost for greater throughput in the future. - Filter Plates

Feature: Lightweight polypropylene with excellent corrosion resistance. Replaceable wear components in critical areas.

Advantage: Extended plate life and lower operating costs.

- Hydraulic Clamping Cylinders

Feature: Maintains proper clamping force during the press cycle. Cylinders are rugged and easy to maintain.

Advantage: Maintenance costs are minimized. - Diverter Doors

Feature: Close to prevent wash water from entering the cake transport system. Open to allow discharge of cake. Rugged, heavy duty design, automatic operation.

Advantage: Prevents cloth wash water from re-wetting filter cakes after discharge. Minimal maintenance, no operator requirement. - Wash Troughs

Feature: Channel wash water from the diverter doors to a drain. V" bottom with flush nozzles located at each end to prevent solids buildup.

Advantage: Reduces maintenance requirements to clean out clogged troughs.

H Model

- The H model incorporates a single, long stroke, hydraulic cylinder to close and clamp the plate stack and move the plates for cake discharge. Plates are linked together, allowing the filter cakes to discharge simultaneously as the press is pulled open by the hydraulic cylinder. The H model is available with up to 50 filter chambers for a throughput capacity of up to 65 tonnes/hour on a typical mineral concentrate.

S Model

- The S model incorporates four short stroke hydraulic cylinders to clamp the plate stack and a plate traveler mechanism to retract the follower. Plates are moved by a mechanical chain drive system and are linked together, allowing the filter cakes to discharge as the press is pulled open by the drive assembly. The S model is available with up to 64 filter chambers for a throughput capacity of up to 90 tonnes/hour on a typical mineral concentrate.

D Model

- Ideal for larger operations, the D model incorporates many of the same features as the S model, with four short stroke hydraulic cylinders, a mechanical drive system for cake discharge, and linked plates. Both ends of the D model press move simultaneously, further increasing efficiency by speeding cake discharge. The D model is available with up to 130 filter chambers for a throughput capacity of up to 170 tonnes/hour on a typical mineral concentrate