Disinfectants can react with natural materials in source water to form disinfectant byproducts. The most common disinfectant byproducts are Trihalomethanes (THMs), Haloacetic acids (HAA), Chlorite, and Bromate which are produced when chlorine reacts with natural organic matter in the water. The identification of these disinfection byproducts (DBPs) in chlorinated water has led to concerns over potential health effects, such as reproductive issues and cancer.

What is the Disinfectants and Disinfection Byproducts Rule?

The Disinfectants and Disinfection Byproducts Rule (DBPR) is a 2 Stage rule but in place to improve drinking water quality by reducing exposure to disinfection byproducts. If drinking water is treated improperly and consumed over years it may increase overall health risks.

Stage 1 Disinfectants and Disinfection Byproducts Rule: Applies to community water systems and non transient non-community systems that add disinfectants to drinking water. This rule set 7 standards to reduce disinfectant byproduct exposure. Routine monitoring requirements including regulated contaminants, MCL (mg/L), MRDL (mg/L), analytical method, preservative, holding time sample/extract, and sample container size and type.

Stage 2 Disinfectants and Disinfection Byproducts Rule: This rule targets public water systems at the greatest risk by setting a maximum containment level (MCl) of 0.08 mg/L for THMs in drinking water and 0.06 mg/L for HAA5.

The Stage 1 and Stage 2 Disinfectants and Disinfection Byproducts Rules address risk from microbial pathogens and disinfectant byproducts. The main focus is to limit exposure to total trihalomethanes (THMs) and five haloacetic acides (HAA5) specifically. The rules apply to all community water systems and non-transient non-community water systems that add disinfectants including chlorine dioxide. These rules do not apply to water systems that use ultraviolet or UV light disinfection technologies.

Disinfectants used to treat microbial pathogens can react with organic material to create disinfection byproducts

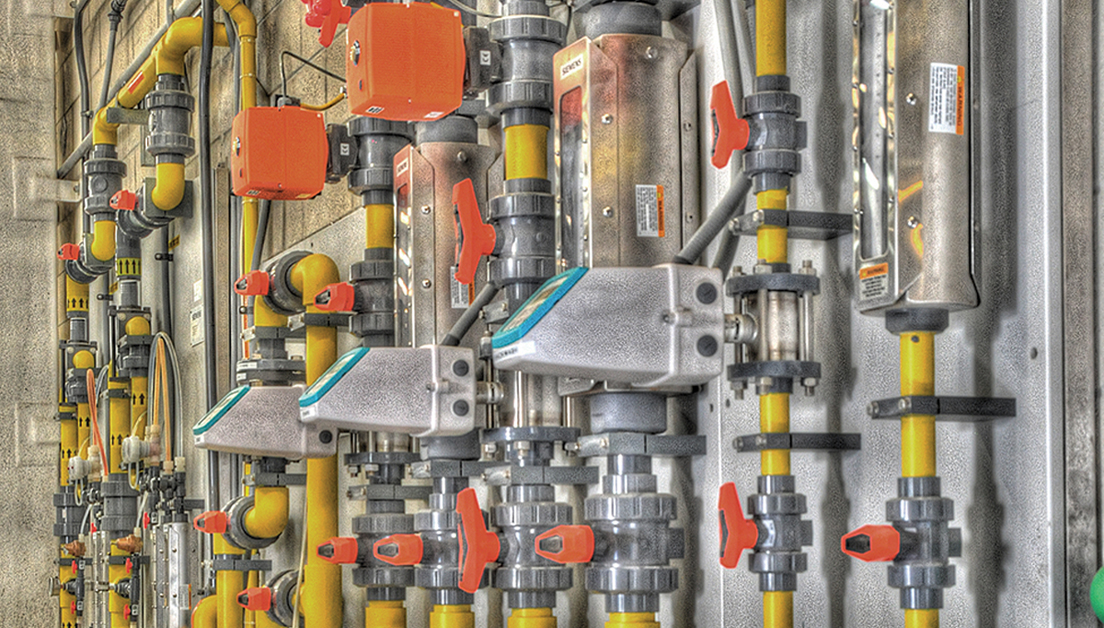

Disinfection Byproducts Proper Treatment and Solutions

In contrast with chlorine, neither chlorine dioxide nor ozone react with naturally occurring organic materials to form THMs or HAA5. These technologies actually prevent the formation of THM and HAA5 by oxidizing their precursors. As a result, chlorination may be moved downstream after most of the nominal organic matter has been removed.

In addition to chlorine dioxide or ozone, ultraviolet (UV) light can be used to provide primary disinfection since it does not lead to THM and HAA5 formation. Evoqua offers a range of chlorine dioxide, ozone and UV solutions that can help you maintain compliance with the Stage 2 Disinfection Byproducts Rule.