As wastewater treatment technologies have advanced, there are now many different ways to treat wastewater in an activated sludge process. Each process and device that accompany it require a number of considerations. Capital costs and the expected electricity, operation, and maintenance (O&M) expenses aren’t the only things to consider. Aeration power, oxygen transfer efficiency, and maintenance must also be factored in.

It can be daunting trying to figure out which of the many aeration devices available today is the best suited for your facility. We have developed the questions below to help guide you through how to compare aeration processes and devices to find the best solution for your application.

What types of aeration devices are available for treating wastewater in an activated sludge process?

Vertical or horizontal low speed aerators, diffusers, and jet aeration are the three main aeration devices. Vertical- or horizontal low speed aerators are typically used in Mechanical Surface Aeration while sequencing batch reactor (SBR) requires either diffused aeration or jet aeration.

What considerations apply when selecting the most effective aeration devices?

Each process requires a different set of equipment and system considerations. Some considerations need to be taken into account, such as whether or not there is a continuous flow or a sequencing batch reactor (SBR). Continuous flow systems require a series of sequential tanks to achieve nutrient removal with varying degrees of treatment. Meanwhile, SBR is a process that can accomplish in one tank the same treatment that requires multiple tanks a continuous flow system. Both methods are used to meet current requirements for low nutrient effluent.

How is oxygen transfer efficiency measured across the different aeration processes?

Oxygen transfer efficiency is measured in tap water at standard conditions of 20°C and 0 mg/l oxygen at sea level. There are a number of different methods that arrive at this standard, with the most common to drive oxygen to zero using sodium sulfite and measure the slope of oxygen rise while aerating with the selected device (i.e., jet aeration). The amount of oxygen rise per hour is the standard aeration efficiency (SAE) value.

What are typical aeration efficiency values?

The typical SAE for fine bubble diffusers is 7.0 to 10.0 lb O2/hp-h. Low speed aeration typically is approximately 3.5 lb O2/hp-h. Jet Aeration is typically about 4.5-5.5 lb O2/hp-h.

What other factors affect efficiency?

Alpha factors and the ability to aerate at zero dissolved oxygen have the biggest impact on aeration efficiency. Alpha factor is the ratio of wastewater efficiency to clean water efficiency. Multi-channel oxidation ditches and SBRs can be just as efficient for aeration as a traditional fine bubble system, although they have lower SAE. This is countered with higher alpha factors and the ability to aerate at zero dissolved oxygen.

Fine bubble diffused aeration can also be used to aerate at zero dissolved oxygen, but some issues arise. At low dissolved oxygen levels and low oxygen demand, a very low hp is required for aeration. The hp for aeration may not be sufficient to keep the solids suspended and settling begins to occur. In addition, blowers may not have the turndown capacity required to maintain these low dissolved oxygen levels. Even though diffused aeration is high efficiency with clean water, lower alpha factors and the ability to aerate at zero dissolved oxygen do not perform as effectively in wastewater. Meanwhile, surface aeration in an oxidation ditch has a much greater turndown on aeration while still maintaining mixing.

Additionally, factors like tank depth also impact the efficiency of aeration devices when located near the tank floor, such as fine bubble diffusers and jet aeration. For instance, a 3-m-deep (10-ft-deep) tank might achieve 25% oxygen transfer, but a 6.1-m-deep (20-ft-deep) tank likely will achieve about 45%. However, when tanks get too deep, the increase in oxygen transfer drops off and blower pressures keep increasing. Tanks between 6-m- and 8-m-deep (20- and 25-ft-deep) are the typical sweet spot for optimum oxygen transfer with diffused aeration. Low speed aerators rely on surface aeration and are unaffected by depth.

What factors should be considered when determining aeration cost?

What factors should be considered when determining aeration cost?

When selecting aeration devices, all expenses need to be considered to determine the best fit. Lifecycle cost of the equipment is one of the most important considerations as this includes required maintenance, loss of efficiency from lack of maintenance, and eventual replacement. Electricity cost must also be a factor, and while aeration is the biggest electricity cost, in most facilities the labor cost is significantly higher.

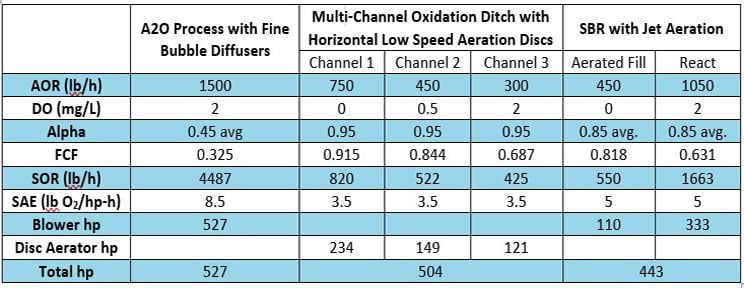

How does aeration power compare across the aeration processes?

The chart below shows that multi-channel oxidation ditches and SBRs can be just as efficient for aeration as a traditional fine bubble system. Although they have lower SAE, it is countered with higher alpha factors and the ability to aerate at zero dissolved oxygen.

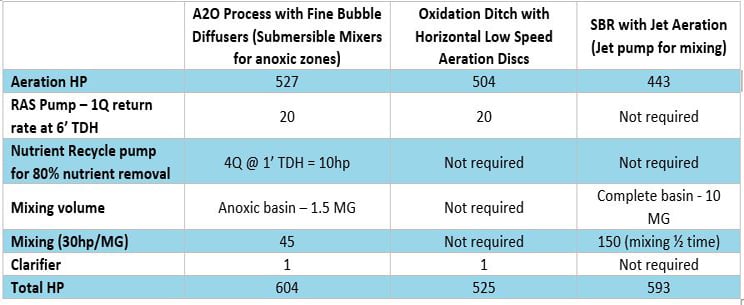

How to calculate total energy costs across the different aeration processes?

Energy requirements differ for each aeration process due to the specific nature of treatment and nutrient removal involved. The chart below factors in various mixing costs and other related equipment costs to determine a total power comparison for different processes.

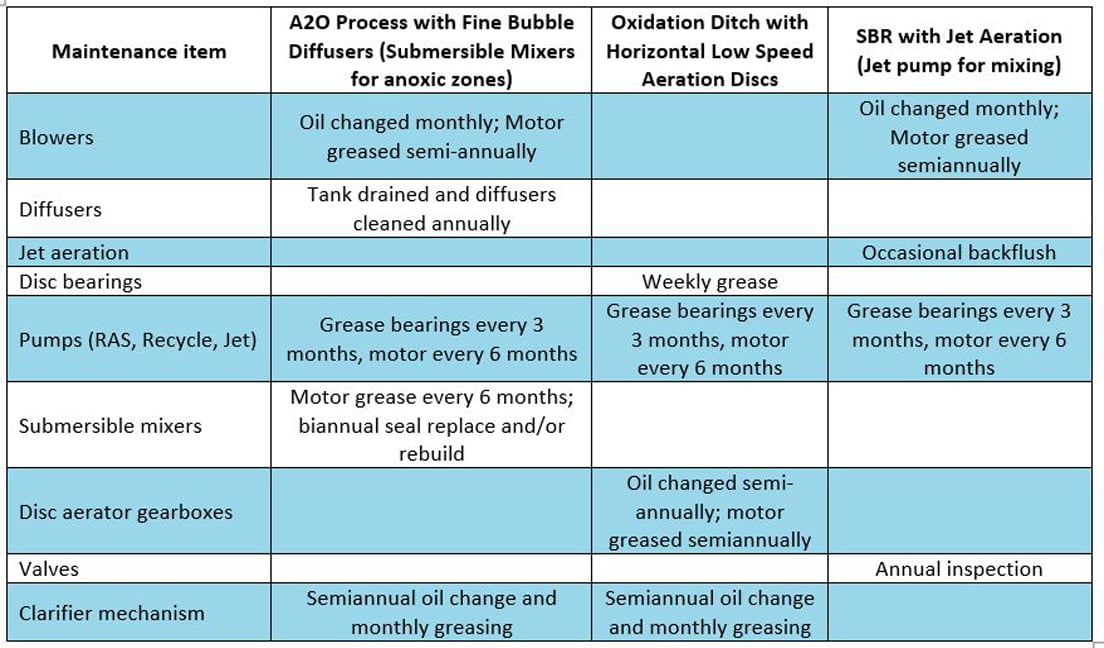

How do maintenance costs compare across the aeration processes?

When considering options for your facility, evaluating both the energy and operations and maintenance costs will help yield a design that is efficient for both energy and operation. Total costs depend on highly variable labor costs in addition to required maintenance. Systems with blowers and diffusers require more maintenance than mechanical aeration, while fine bubble diffusers may have higher operating costs depending on degree of efficiency lost compared to the cost of cleaning. Using guidance in the following table, approximate maintenance costs can be estimated depending on local labor rates and should be weighed against the energy costs for aeration and mixing.