Northumbrian Water provides water supply and sewerage services to a population of 2.7m in the north east and 1.8m in the south east of England, delivering 1,100 MLD of drinking water. Potable water treatment works vary from small groundwater sources to large surface water treatment facilities. Their Mosswood Water Treatment Works in County Durham treats 135 MLD of water by clarification, filtration and chlorination.

Challenge

Northumbrian Water needed to improve reliability and resilience at the works by installing a multi-barrier process against chlorine resistant organisms like Cryptosporidium.

Northumbrian Water is no stranger to UV technology – it is widely used for groundwater treatment and for wastewater disinfection in their area – so this was the obvious choice for Cryptosporidium control. However, retrofitting UV into an existing works, particularly one of the size of Mosswood, with large diameter pipework, is always a technical challenge. The valves and pipework around Mosswood’s twelve rapid gravity filters made the filter gallery quite congested, and the project team was planning a new disinfection building to house the UV equipment along with pumping from the filtered water channel.

Solution

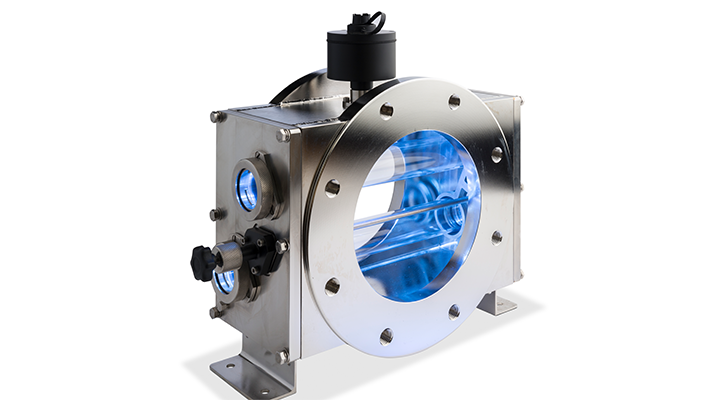

Evoqua’s proposed solution was to install a Wafer® UV system into the outlet of each of the twelve rapid gravity filters within the filter gallery, each with its own independent monitoring of UV intensity, this arrangement gives much more resilience than the more usual duty/assist/standby configuration. The ultra-compact Wafer UV system was developed to provide very high UV performance in the smallest footprint possible; a key factor in the selection of this reactor. Access for maintenance was also a major consideration, but the Twistlok™ UV lamp connection features a plug-and-play mechanical interlock and improved quartz seal compression for high reliability and safer and faster maintenance. The Wafer control system continuously monitors UV transmittance and UV intensity in each system and automatically adjusts the power to the lamps to optimise the UV dose and minimise energy consumption.

Installing the UV systems in the existing filter gallery meant that there would be no need to break ground and build the new disinfection building. In addition, due to the low headloss through the Wafer® UV system, no additional pumping stage would be required, keeping energy consumption and carbon footprint to a minimum. The proposal would almost halve the initial project cost estimate.

In November 2019, Northumbrian Water decided on a trial involving the fitting of a UV system into one of the filter outlets. Thanks to early engagement and excellent collaboration between all the key stakeholders and suppliers, the Wafer UV system installation went smoothly and, in spite of the COVID-19 lockdown, was completed on time in early June 2020. The trial was so successful that Northumbrian Water is now making significant investments to install similar units on the other eleven filters by the end of 2022.

Results

This is the first time that Northumbrian Water has used ultraviolet technology to treat filtered water in a surface water treatment works, and they are the first water utility in the UK to use the Wafer UV system in this application. There was some initial scepticism, which is why the trial was considered necessary, but this has been replaced by confidence.

Pictured (left to right): Before the Wafer UV system installation and the modified filter outlet pipework after the compact Wafer UV system had been installed.

" It’s massively exceeded our expectations and will help us to improve the quality of water received by our customers, as well as making sure the treatment works is reliable and resilient, long into the future. "