The Fredericksburg Sewer & Water Authority (FSWA) owns and operates two wastewater treatment plants, five wastewater pumping stations, three wells and three water storage facilities.

Proposed residential and business growth and a mandate by the Pennsylvania Department of Environmental Protection (PADEP) required FSWA to provide a wastewater treatment plant for the South Fredericksburg area. The imposed mandate was due to soils in the area being unsuitable for on-lot septic systems. Many of the existing systems in the area were failing or had suspected failures that lead to contamination of the wells used by many of the residents.

Challenge

The original wastewater treatment plant utilized chlorine disinfection. Awareness of the environmental toll and long-term public health of chemical disinfection, led the Environmental Protection Agency (EPA) to establish regulations to residual chlorine limits and disinfection byproducts (DBPs). When chlorine is added to wastewater, it can alter organic matter by forming disinfection byproducts. The EPA believes there is sufficient association between DBPs and potential health hazards to warrant regulation.

Solution

The FSWA constructed The Little Swatara Creek Wastewater Treatment plant to accommodate serving the current population and the proposed residential and business growth. There has seen an increasing demand due to the growing chicken processing industry in the area. The WWTP utilizes a sequencing batch reactor plant (SBR) for biological treatment and serves the residents and businesses of the Village of Fredericksburg as well as the newly connected South Fredericksburg Service area.

The FSWA is always looking for ways to reduce operating costs while maintaining or improving service to their customers. The consulting firm on the project was Steckbeck Engineering & Surveying, Inc. When selecting the technologies for the new plant, energy savings, low construction cost and reduced footprint were a priority, while meeting permit limits. The WWTP was constructed using state of the art controls and software for operations. To help achieve energy savings, LED lighting was installed throughout the plant. The result has proven to be utilizing the same amount of electricity as the old plant while treating more wastewater to a greater level daily.

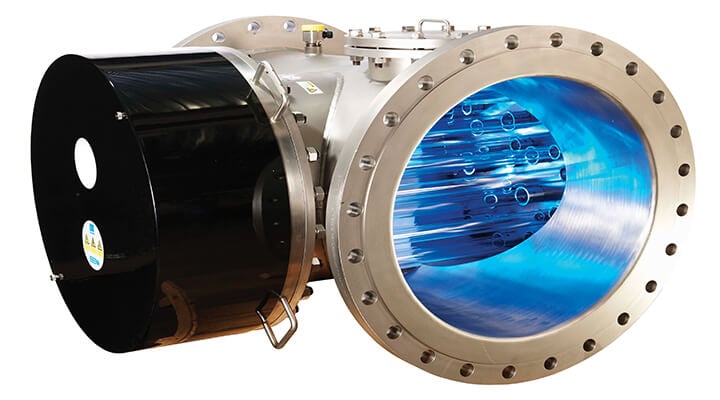

Three ETS-UV™ SW systems were installed at the FSWA facility. Each UV chamber is designed for a peak flow of 0.65 MGD to meet the permit coliform limit of 200/100ml. Future expansion of the WWTP will treat average flow of 0.650 MGD and peak flow of 1.62 MGD will include construction of a third SBR basin and installation of a fourth UV unit. Traditionally, wastewater UV systems were constructed as an open channel system, utilizing racks of lamps immersed into a channel. These open gravity flow channels suffer from many disadvantages; poor hydraulic mixing, very large footprint, expensive to build, difficult to maintain and are vulnerable to fluctuations in flowrate. Disinfection in a closed pipe will ensure optimized hydraulics and prevent exposing the operator to wastewater and UV light.

" After reviewing UV disinfection units from multiple manufacturers, we chose the ETS-UV systems for their disinfection efficiency, ease of installation and maintenance, selfcleaning feature, and small footprint. The ETS-UV units assisted the Operator in meeting the discharge permit limits from the first day of plant operations. "

Results

UV disinfection eliminates the need to generate, handle, transport, or store toxic/hazardous or corrosive chemicals and requires less space than other methods. In addition, UV leaves no residuals that can be harmful to humans or aquatic life and it is safer for plant operators. ETS-UV disinfection systems are designed with sophisticated UV monitoring and controls to ensure consistent effective performance and an automatic wiping system to keep quartz sleeves clean to prevent lamps from fouling.