Challenge

The German Echthausen Water Works is one of eight water works of Wasserwerke Westfalen GmbH, located in Dortmund, Germany. It was built in 1942. Wasserwerke Westfalen is a subsidiary company of both Dortmunder Energie- und Wasserversorgung GmbH and Gelsenwasser AG, and is the largest producer of drinking water in the German state of North Rhine-Westphalia. It delivers 105 million cubic meters of drinking water per year (76 million gallons per day) to both companies. Echthausen Water Works supplies 20 communities with some 20 million cubic meters (706.3 million cubic feet) of drinking water, 20 per cent of the whole delivery rate.

35 hectare (86.5 acres) water catchment terrain are available for the water works Echthausen. After the initial pre-cleaning through a fine screen, flocculation if necessary, sedimentation and the dosing of activated carbon the main cleaning follows, with slow sand filtration, underground passage and partial re-infiltration of the first filtrate. The final treatment includes the dosing of sodium hydroxide for a higher pH value. Up to now chlorine dioxide solution was dosed at the end. If the chlorine dioxide generator fails a sodium hypochlorite solution can be added as well.

Management at Wasserwerke Westfalen wanted to modernize and upgrade its facility with leading-edge, environmentally friendly technologies. They also wanted to upgrade their safety and cost effectiveness by replacing their chlorine dioxide disinfection system with UV disinfection. UV is more effective against possible pathogens. Handling of chemicals can be avoided, what means more safety for the employees. The taste of the UV treated water stays unmodified. This was also important for the operators’ decision of the most applicable disinfection method.

Solution

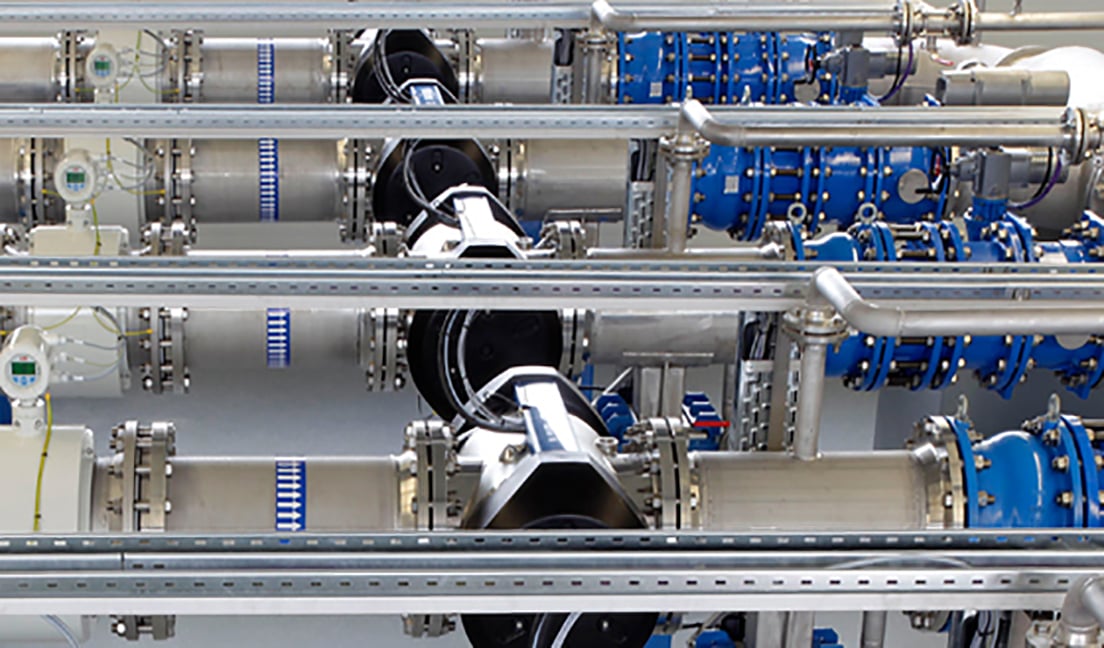

The managing operators in Germany considered several suppliers – only Evoqua Water Technologies UV systems with an integrated control unit and from a single source met their requirements. Thus, in Echthausen five Barrier® M UV systems were installed. This unit encloses medium pressure lamps and is DVGW certified, which is approved for the disinfection of potable water in Germany. The UV systems, installed in May 2010, are operated in parallel, at the end of the water treatment. This means high safety for the disinfection – even if one unit fails. They have an average of 2,200 (9,700 US gpm) and a maximum throughput of 4,000 cubic meters of water per hour (17,600 US gpm). Each plant can be separately controlled to match requirements. The continuously variable control of the intensity of irradiation delivers exactly the required “dose”. Electronic control ballasts ensure high efficiency: combining the safest possible disinfection with energy-saving operation. The Simatic® PCS7 process control system is used to control the plants. This enables the UV disinfection stage to be seamlessly integrated into Wasserwerke Westfalen‘s overall control concept, which is also based on PCS7. The peripheral equipment is connected by ET200 signal modules and communications via Profibus® protocol are also integrated. The UV plants can be operated the WinCC® HMI system from the local Echthausen works control center or from the control center in Hengsen. Results The Wasserwerke Westfalen anticipate they will reduce their annual consumption of chlorine dioxide by 20 tons. In the following years the other water works facilities will be upgraded and rebuilt in the same way.

Results

The Wasserwerke Westfalen anticipate they will reduce their annual consumption of chlorine dioxide by 20 tons. In the following years the other water works facilities will be upgraded and rebuilt in the same way.