Generating ultrapure water (UPW) is a critical step in microelectronics manufacturing. Get the quality of UPW right and production output will be protected, while wider operational benefits are realised, get it wrong and the result can be costly. Evoqua has been working closely with the microelectronics industry, providing technology solutions and support that improve and enhance manufacturing processes. Here, our director of product management, Patrick Buzzell, has answered the frequently asked questions on UPW generation, from boron removal through to safety and maintenance of systems.

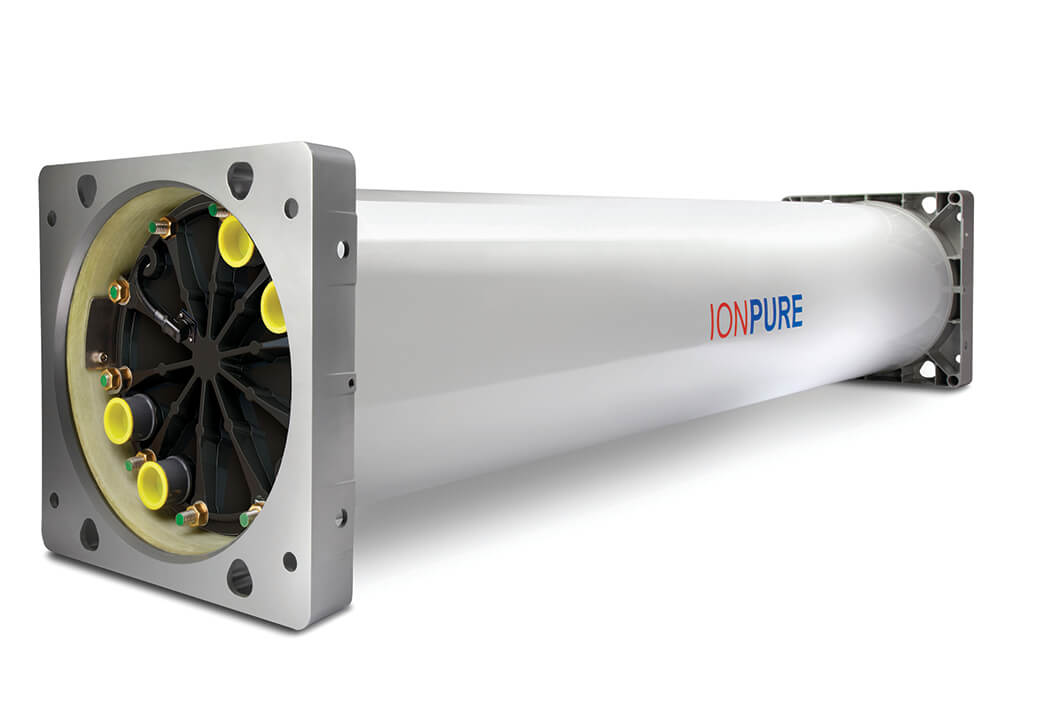

Today, continuous electrodeionisation (CEDI) is the leading technology for UPW production. Our innovative Ionpure® CEDI system works by combining resin, electricity, and ion-exchange membranes to remove ionised or ionisable impurities – including carbon dioxide, boron, and silica. Unlike traditional processes, such as mixed bed deionisation (MBDI), CEDI is a continuous low energy consuming process and avoids the need for chemical regenerants, which delivers a wide range of benefits to manufacturers. Let’s dive into the questions to explain more.

How safe is a CEDI system to have on site?

One of the key advantages of the Evoqua Ionpure CEDI technology is the safety benefits it delivers against traditional MBDI processes. These safety benefits are nothing short of incredible, as CEDI eliminates the handling and storage of hazardous chemicals. Typical regenerant chemicals are produced by the chlor-alkali industry producing sodium hydroxide (NaOH) along with chlorine gas (Cl2) and hydrogen (H2). Chlorine gas and hydrogen are then synthesized into hydrogen chloride gas which can be dissolved in water to produce purified HCl. Keeping employees safe is critical and we know this is a priority for all manufacturers. Serious or even fatal injury is sadly a reality worldwide when dealing with chemicals, such as acid and caustic, which are present in MBDI systems due to the need for chemical regeneration. So, moving to CEDI, operating in a chemical free process, delivers vital safety benefits.

What are the maintenance requirements of the Ionpure® system?

Maintenance requirements are very low for the Ionpure system, which is one of the significant benefits of using CEDI technology. Versus traditional methods of deionisation, manufacturers will notice a huge difference in operational time saved and the costs associated with this.

How long does a CEDI system last?

The typical lifespan of an Ionpure CEDI modules is 5-7 years and, as mentioned in the previous question, the minimal maintenance requirements throughout this time are market leading. Once a system has come to the end of its life, replacing an Ionpure module is quick and simple. For added peace of mind, we offer global servicing and support for all our technology.

How can a CEDI system support my organisation’s sustainability goals?

We’re very proud of how our Ionpure modules support sustainability. Firstly, the technology removes a waste stream versus traditional MBDI as there is no resin, regeneration chemicals, and neutralization required. Secondly, chemical transport emissions are eradicated as CEDI is a chemical free process. Thirdly, the system is energy efficient, reducing energy usage compared to MBDI. Importantly, as well as the environmental savings, these benefits also offer financial savings for manufacturers.

Can CEDI effectively remove boron?

As boron is one of the more challenging contaminants when it comes to deionisation due its weakly charged nature, it’s no surprise this is a question we get asked a lot. And the answer is a firm yes! Our state-of-the-art Ionpure VNX-Ultra has been developed and optimised for the microelectronics industry for this purpose. It’s extremely effective at removing boron from UPW, with boron and silica removal ≥ 99.8% and sodium and chloride removal ≥ 99.9%. This class-leading technology is our most powerful Ionpure module to date. It can effectively hit 1 ppt boron in a single pass set-up configuration and no requirement for boron selective resin.

To find out more about our Ionpure® systems and the most effective UPW generation technology for the microelectronics sector, contact us today!