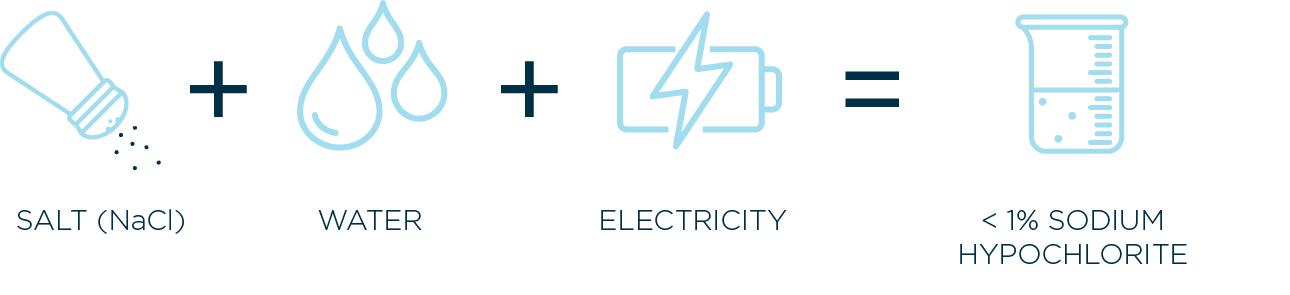

On-site electro-chlorination systems produce sodium hypochlorite – a low-strength disinfectant[1] used to treat water in many different industries, including food and beverage manufacturers, industrial cooling systems and produce washing.

But why is it so popular?

Evoqua has been supplying OSEC® systems for over 30 years, and the benefits are reflected in evolved product design and technical expertise. In-situ production of sodium hypochlorite is a safe alternative to other forms of chlorine disinfection, as the only raw materials that need to be handled by operators are salt and water. This brine solution is then run through a generator that electrolyses the liquid and renders it one of the most effective – and sustainable - disinfectants on the market.

The only ‘chemical’ required on site is salt (sodium chloride) which is non-hazardous and can be conveniently purchased in 25kg bags or delivered in bulk and easily stored on site. It is also widely available, which means security of supply.

OSEC systems reliably produce disinfectant that is safe and stable, giving greater operational flexibility. Because sodium hypochlorite solution is produced on-demand in batches, the system imbues companies with a self-reliance and total confidence they have access to the disinfection supplies they need, without the logistical risk of reliance on a sole chemical supplier.

At any stage, operatives can run a brine solution through the electrolyser to produce the sodium hypochlorite they need right then and there, rather than waiting on the hazardous - and increasingly unsustainable - transport of bulk chemicals to site. It also retains its strength when stored, and can be added to water to disinfect surfaces, produce or containers.

OSEC systems boost sustainability by helping to reduce the carbon footprint of companies by lowering the emissions required to transport bulk hypochlorite (which can be up to 90% water). These lumbering, double-bunded trucks carry dangerous chemical loads and contribute heavily to the environmental carbon footprint. And any supply chain difficulties causing a delay in delivery can mean operational shutdown: lost revenue, dissatisfied customers, and potential brand damage.

So where are OSEC systems used?

OSEC systems are designed for simple installation and ease of use with minimal maintenance, and because of this, are widely used.

The small footprint of the OSEC generator units is suited to many applications and hard-to-get-to locations across municipal, aquatics and industrial markets.

Industry manufacturers often use small OSEC systems in their plants, as the low concentration of sodium hypochlorite gives better control in applications like produce washing and disinfection of equipment.

Utilising in-situ generation of sodium hypochlorite provides industry manufacturers with the flexibility to produce their own sustainable, safe disinfectant, and utilise it across multiple applications. For example, sodium hypochlorite added to water can destroy microbes present in food preparation. It is also a proven solution for disinfection of production equipment, food preparation surfaces and transportation containers.

Health and safety priorities

Evoqua OSEC systems have a long history – more than 30 years in the market - with a best-in-class safety record.

The core value of the OSEC system is design-engineering around safety. From installation to the end of the line, the systems are meticulously engineered to optimize all safety features. The objective is to ensure that everyone gets home safely - and that the customer gets the correct disinfection solution to meet their needs.

This is great for the industrial sector because employees in food and beverage, or IT and datacentres for example are not - by definition - experts in handling dangerous chemicals. Operators in the municipal and aquatics markets have water disinfection as their primary activity - keeping swimming pools healthy or ensuring potable water is safe to drink. Industrial employees tend to use water disinfection solutions as an ancillary activity, so safer options are a plus.

The elevated safety levels of OSEC systems means that industrial employees do not have to be highly trained as chemical handling experts. Handling or spilling of salt and water is not hazardous and lessens the likelihood of contamination and leaching.

On-site generation reduces the risk of environmental damage from the storage and handling of bulk chemicals and through leaks in pipework, as bulk hypochlorite can cause degradation to pipes through calcium build-up. With no need for chemicals to be transported and delivered to the plant, the risk to the environment is reduced.

Another advantage of the on-site process is that chlorine lowers the pH when compared to bulk hypochlorite, improving the efficiency of the treatment process

The Evoqua OSEC system is a proven, safe, alternative to bulk chemicals, delivering safe, efficient, reliable disinfection without the need for transportation of bulk chemicals. The unit only requires minimal annual maintenance, and the footprint can be smaller than other on-site generators.

Sustainable benefits of hypochlorite include:

- Highly efficient in-situ processing allowing economic production according to the actual demand

- On-site and on-demand generation from inert feedstocks, reducing or eliminating common issues with chemical storage and handling

- Low strength solution at a stable concentration means minimized decomposition of active chlorine in solution always available

- Product generated with minimized disinfection by-product formation

- Safe handling for operators

- Cost savings via off-peak production scheduling

- Less transport of bulk chemicals, lowering emissions, and reducing carbon footprint

- Attractive to industrial sectors who want to retain core focus and approach water disinfection safely and with confidence

- Reduced OpEx and greater sustainability over time.

The Evoqua OSEC® system is a proven, safe, alternative to bulk chemical deliveries (an alternative of neat chlorine deliveries, commercial bleach, and chlorine tablets) delivering safe, efficient, reliable disinfection without the need for transportation of bulk chemicals. The unit only requires minimal annual maintenance, and the footprint can be smaller than other on-site generators.