Sustainability is of increasing importance in the Food and Beverage industry, and many businesses are seeking new alternatives to their existing treatment processes. Let's take a closer look at medium-pressure UV systems, which offer a 2-in-1 solution with simultaneous disinfection and dechlorination for greater environmental savings.

Chlorination is a widely used method for water disinfection, but it has its downsides. For mains supply, residual chlorine helps to ensure disinfection all the way through to the end user, but for the food and beverage industry, it can affect the organoleptic properties of products. That is why many businesses are turning to medium-pressure UV systems, also known as high-intensity broad-spectrum UV systems.

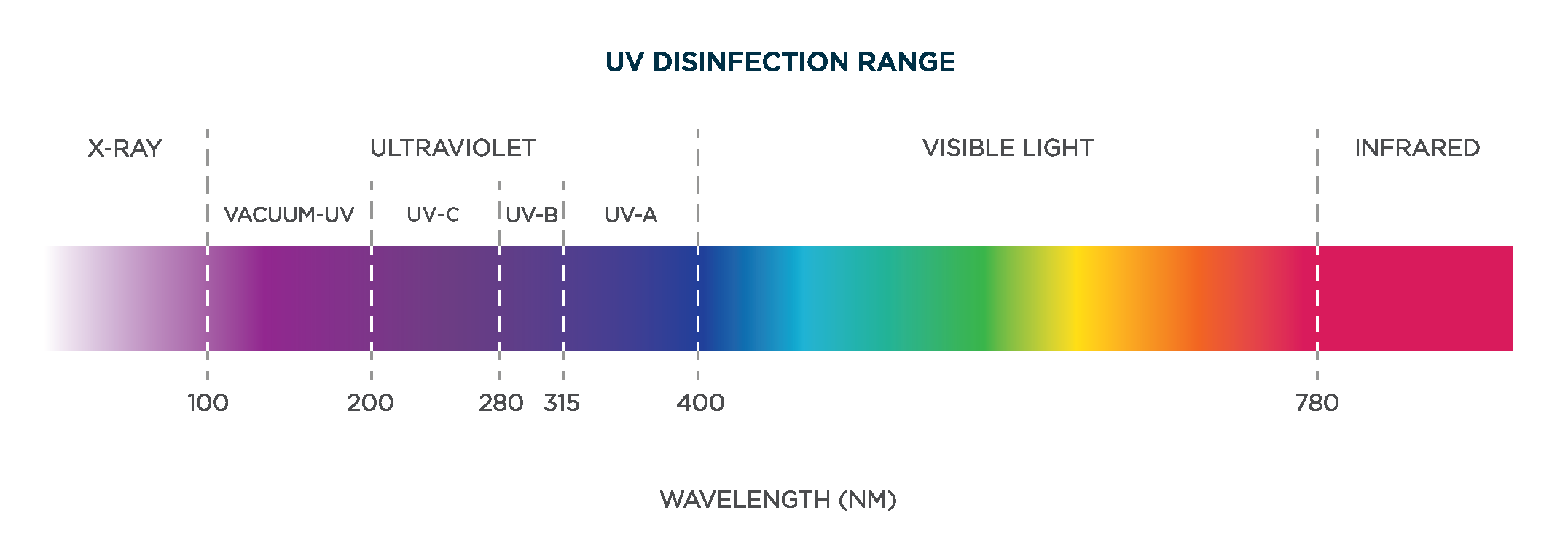

Medium-pressure UV systems are proven to effectively reduce free chlorine in water with concentrations up to 5mg/l. This reduction is achieved using UV light wavelengths of 180-400nm, creating photochemical reactions that dissociate free chlorine and combined chlorine compounds.1

One of the main advantages of medium-pressure UV systems is that they do not introduce any poor taste or odor compounds to the water being treated. Equally, they reduce any dependency on treatment chemicals while minimizing associated hazards, labor, and costs. Unlike filtration they do not require media replacement or regular microbial sanitization, which helps to keep equipment cleaner and operational costs lower.

Granular activated carbon (GAC) beds and sodium metabisulphite are popular methods for dechlorination, but they each have notable disadvantages. GAC beds can experience excessive pressure drop and exhaust their capacity for chlorine absorption, requiring regular replacement and/or backwash cycles that add time and costs to the dechlorination process. Furthermore, the porous structure of GAC beds can become a breeding ground for microbial growth, which may require sanitization.

In contrast, medium-pressure UV systems offer water dechlorination with high levels of consistency and effectiveness, even with minimal head loss. Most notably, they are superior from an environmental perspective. They are:

- Energy-efficient

- Reduce chemical requirements

- And enable greater water reuse

All which make them a more sustainable option for many applications.

While fulfilling their primary function in dechlorination, medium-pressure UV systems also provide excellent disinfection. The systems are effective against a wide range of microorganisms, including chlorine-resistant pathogens like cryptosporidium.*

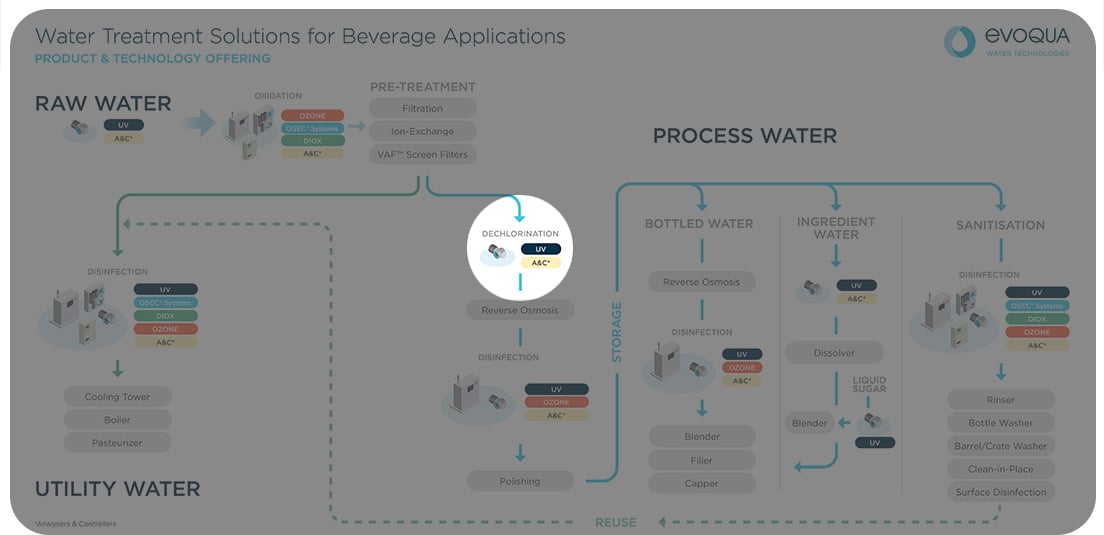

Dechlorination: One of the many UV applications in the water treatment solutions in beverage applications.

Evoqua Water Technologies offers a range of UV dechlorination systems that have been developed using scientific knowledge gathered over the past 20 years. These systems are not only suitable for use in the food and beverage industry, but also in the microelectronics, pharmaceutical, and healthcare sectors.

If you're looking for a sustainable solution for water disinfection and dechlorination, consider the benefits of medium-pressure UV systems and get in touch with our team today.

1 Kyungjin Cho, Seongpil Jeong, Heesun Kim, Kwanho Choi, Seockheon Lee, Hyokwan Bae, Simultaneous dechlorination and disinfection using vacuum UV irradiation for SWRO process, Desalination, Volume 398, 2016, Pages 22-29, ISSN 0011-9164

Evoqua UV disinfection generator systems undergo third-party validation testing in accordance with the UVDGM (USEPA, 2006). Validated products are tested to confirm a minimum inactivation equivalent of 3 log (99.9%) for microorganisms in accordance with NSF/ANSI 50 and the UVDGM. Performance is not claimed nor implied for any product not yet validated; unvalidated products use single point summation calculations to provide delivered dose recommendations. Performance limitations depend on feed conditions, overall installed system design, and operation and maintenance processes; please refer to Operations Manuals. For more information: Contactus@evoqua.com