Dual or Multi Phase Extraction Systems (DPE)

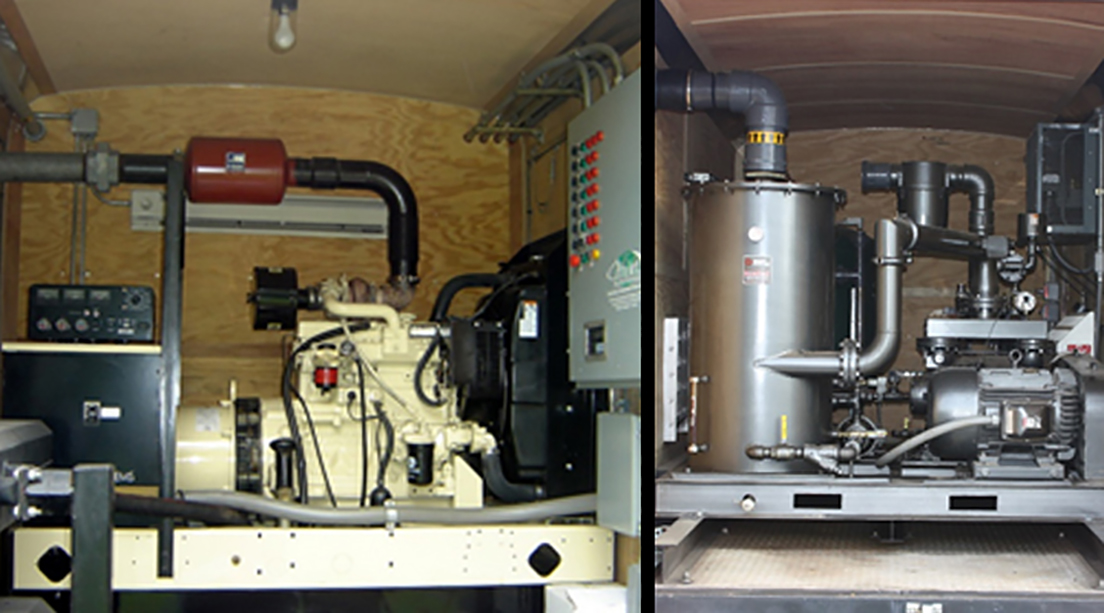

See All Rental Equipment (Mobile & Stationary)Mobile and emergency enclosed treatment trailers simultaneously treating soil vapor and groundwater that is contaminated with semi-volatile and volatile organic compounds.

- is the minimum order quantity for this product. Please check quantity and add to cart again.

Mobile and emergency enclosed treatment trailers simultaneously treating soil vapor and groundwater that is contaminated with semi-volatile and volatile organic compounds.

Description

Evoqua's dual-phase extraction trailers simultaneously treat soil vapor and groundwater that are contaminated with semi-volatile and volatile organic compounds. DPE removes volatile organic compounds (VOC), semi-volatile organic compounds (SVOC), and free phase and dissolved fuels from groundwater and soil.

One or more extraction wells are drilled down to a given depth in the impacted zone. Piping (a stinger) is lowered into each well. The intake of the stinger is placed at the desired level in the well from which the vapor and water is to be extracted.

The DPE vacuum pump creates a very high vacuum that draws contaminated soil vapors out of the soil. It generates suction at the DPE well points. The dual phase extraction vacuum pump pulls contaminated vapors and water from the contaminated zone, through the stinger pipe into a manifold that connects to the knockout tank.

The extracted vapors flow into the knock-out tank, which separates liquid from the vapor. In the knock-out tank, gravity causes the liquid to settle to the bottom of the vessel. The vapor travels upward and exits the top of the vessel. The contaminated water and contaminated vapor leaving the knockout tank follow separate paths as they pass through the rest of the treatment system.

The contaminated vapor leaves the knock-out tank through a particulate filter into the pump. Typically, the vapor passes through a coalescing filter for oil removal. Finally, the vapor flows through a plumbing stack and gets discharged approximately 15 feet above ground. If it is too contaminated for release to the atmosphere it may be mixed with dilution air, if regulations allow. Alternatively, additional treatment (carbon adsorption, etc.) may be done outside the trailer.

The water collected in the knock-out tank undergoes treatment, usually inside the trailer. This may include oil-water separation, particulate filtration, air stripping, or carbon adsorption. Additional treatment outside the trailer may also be used.

Extraction effectiveness depends mainly on soil permeability, contaminant volatility, and the depth of the contaminated zone. More permeable soil gives better results. With deeper wells the vacuum is often lower, making contaminated vapor more difficult to draw. More volatile constituents vaporize more easily, and so are more easily extracted.

Complementary technologies, such as air sparging, may be used to enhance extraction. The separate vapor and soil treatment sequence and configuration is designed to effectively treat the contaminants at each site.

Evoqua has decades of experience designing and operating dual-phase extraction systems, and has several trailers that can be mobilized to your site on short notice. If you have soil or groundwater contaminated with VOCs, contact us to see if dual-phase extraction is the best approach to your problem.

Features

Types of Remediation

Simultaneous Land & Groundwater Remediation