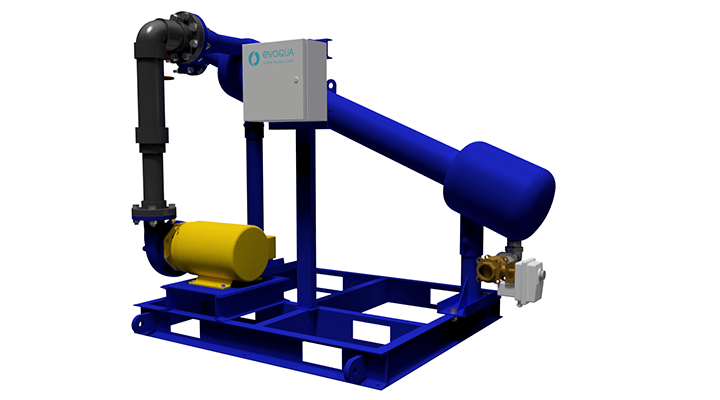

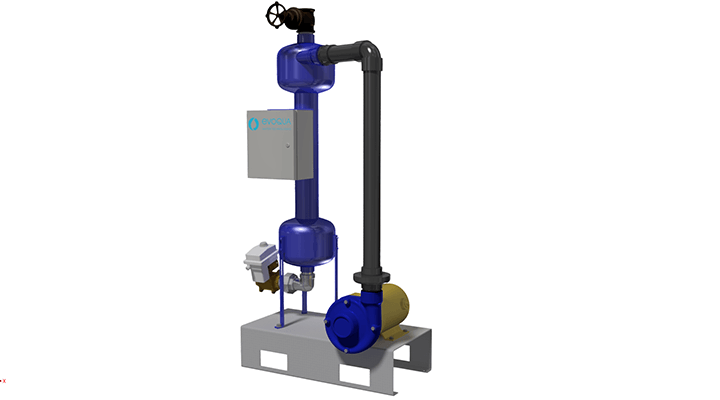

Hydrocyclone Separator Skids

See All VAF™ Screen FiltersEffective solids removal based on specific gravity and flow rate

- is the minimum order quantity for this product. Please check quantity and add to cart again.

- Fully integrated skid package

- Removal of up to 98% of solids 2.6 specific gravity and higher

- Heavy duty construction

- Excellent pretreatment solution to reduce solids load on downstream filtration

- View Gallery

Effective solids removal based on specific gravity and flow rate

- Fully integrated skid package

- Removal of up to 98% of solids 2.6 specific gravity and higher

- Heavy duty construction

- Excellent pretreatment solution to reduce solids load on downstream filtration

Description

Evoqua’s VAF™ brand Hydrocyclone Separators are effective in removing suspended particles from any flow stream of water where the specific gravity (density) of the particle(s) is heavier than the fluid it is in. The more significant the difference in gravity between the water and the particle, the greater the efficiency of the removal process. Depending on the specific gravity of the particle and the viscosity of the flow stream, very small and denser particles can be removed.

Consider a separator's use where any source of water contains contaminants with a weight of 2.6 specific gravity or higher, such as well water to remove sand. Separators are excellent for use in cooling tower open loops or as a pre-removal device for filters with river or ditch water that contain high levels of sand or other large organic debris.

COOLING TOWER TREATMENT SYSTEMS

The LCS and CTS series systems incorporate separator technology to offer low cost and low maintenance options for cooling towers.

LCS-Series

- includes Stainless Steel skid base, VHS separator, outlet throttle valve and auto purge valve. Options include pre-strainer and bag recovery vessel

CTS-Series

- includes upgraded epoxy coated steel railed skid, VHS separator, isolation valve and auto purge valve. Options include pre-strainer and bag recovery vessel

Water Efficiency: The optional recovery bag filter option can be installed on the flush line of the separator and collect and filter out TSS in the system. The cleaned water is sent back to the suction side of the pump for recycle, eliminating any wastewater generation.

HOW IT WORKS

Liquids and solids enter the unit and begin traveling in a circular flow. This centripetal action forces heavier particles downward in a spiral motion to the separation chamber. The particles collect in this separation chamber and are purged from the system. The filtered water is drawn to the separator’s vortex and up through the outlet.

Features

Features

- Removal of up to 98% of solids 2.6 specific gravity and higher at maximum flow rate

- Simple installation through a fully integrated system on skid

- Long Lasting heavy-duty carbon steel with epoxy coating

- Fully automated operation with an automatic purge controller. Eliminates the need for manual flushing

- Minimal maintenance

- Small footprint

- Optional bag filter recovery vessel for zero wastewater