Municipal Wastewater

Helping meet regulatory compliance, reduce cost & reuse water

Municipal Wastewater Applications

View All Applications

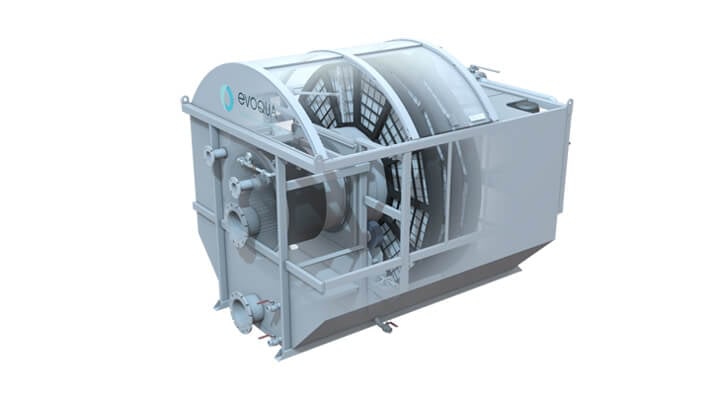

Maximize Treatment Uptime and Equipment Life

Extend the life of equipment, improve performance, and reduce maintenance to keep wastewater treatment plants up and running.

Learn more