Metal Plating

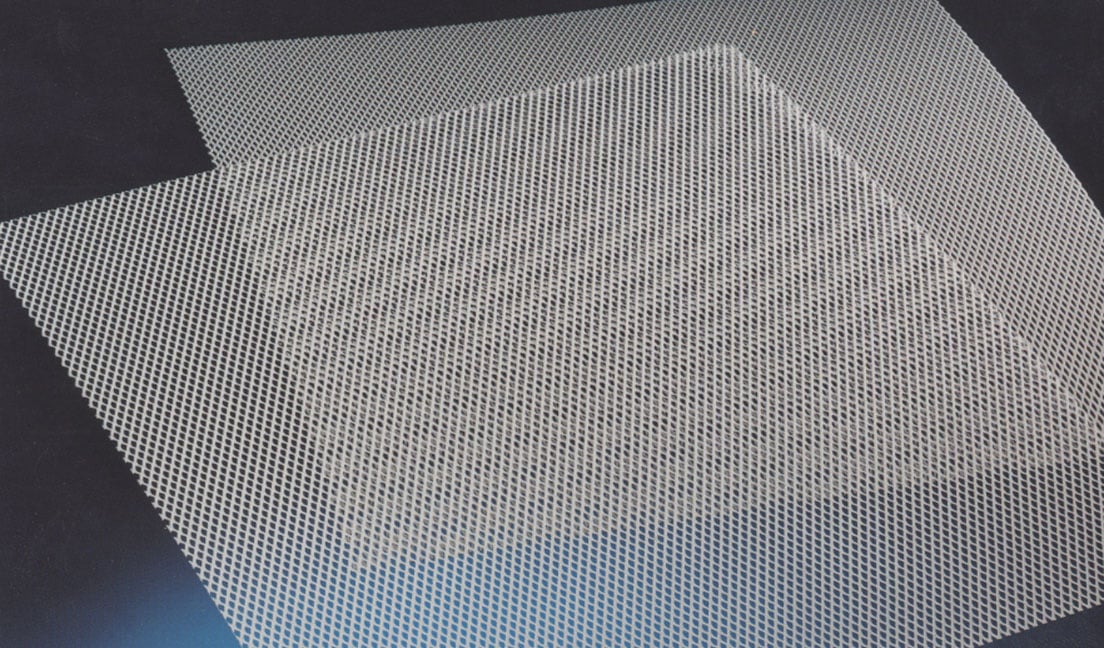

Magneto’s anodes close the electrical loop associated with metal plating applications

Magneto is an industry leader in the innovation and manufacture of anodes for metal plating across a range of applications and industrial processes.

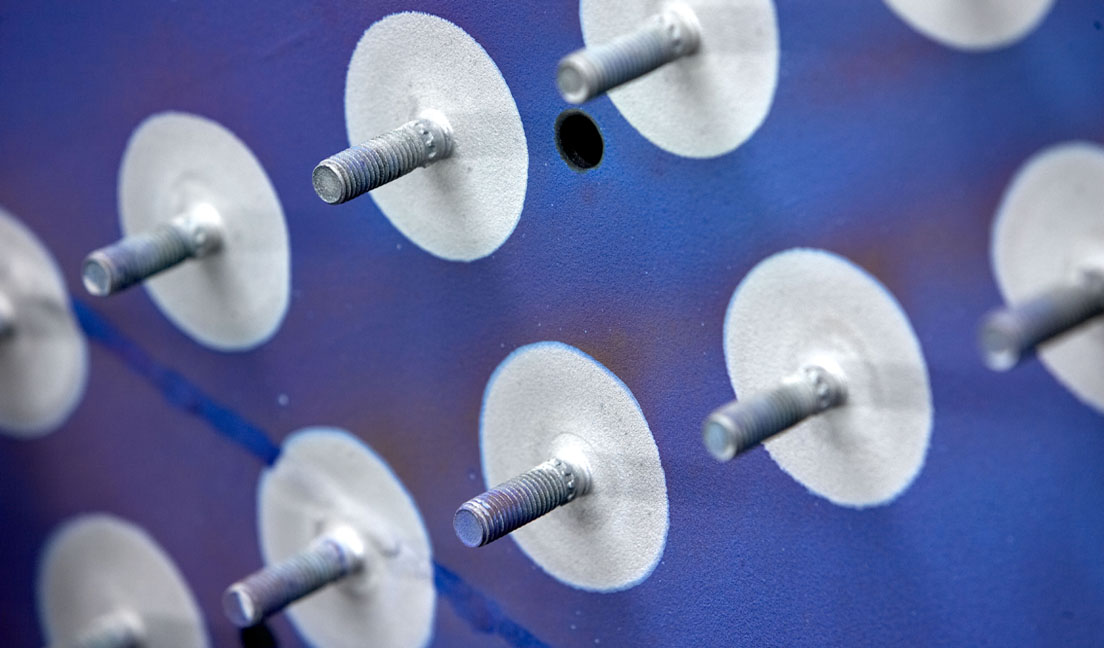

The principle of metal plating is almost identical for all applications. The metal to be plated is dissolved in the electrolyte and the object to be plated is cathodically polarised. Magneto anodes close the electrical loop.

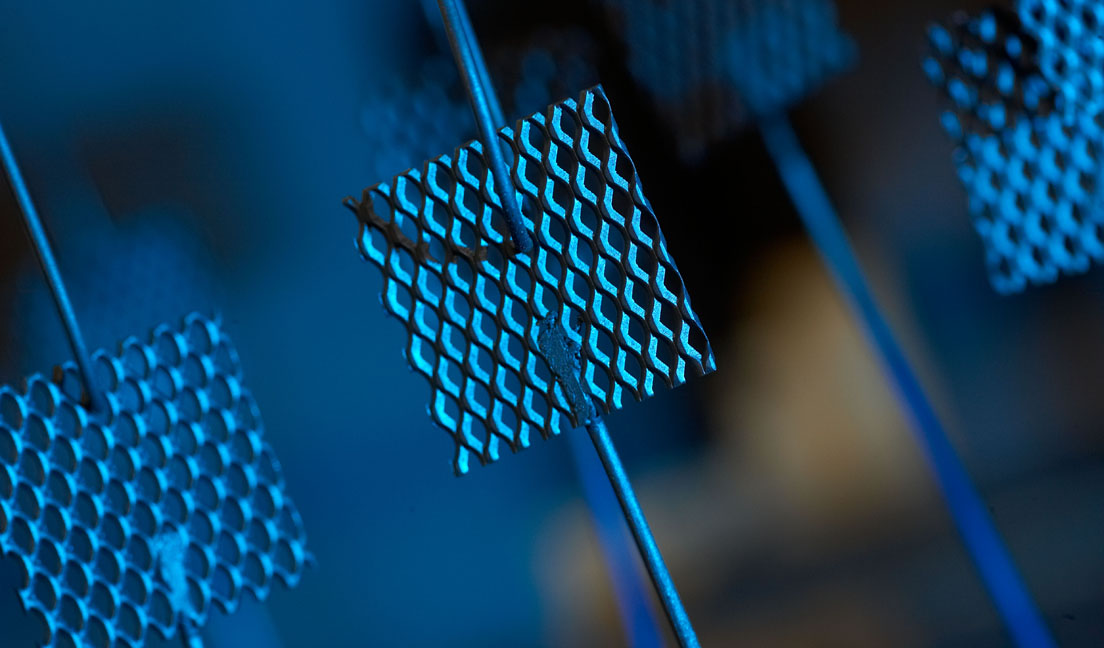

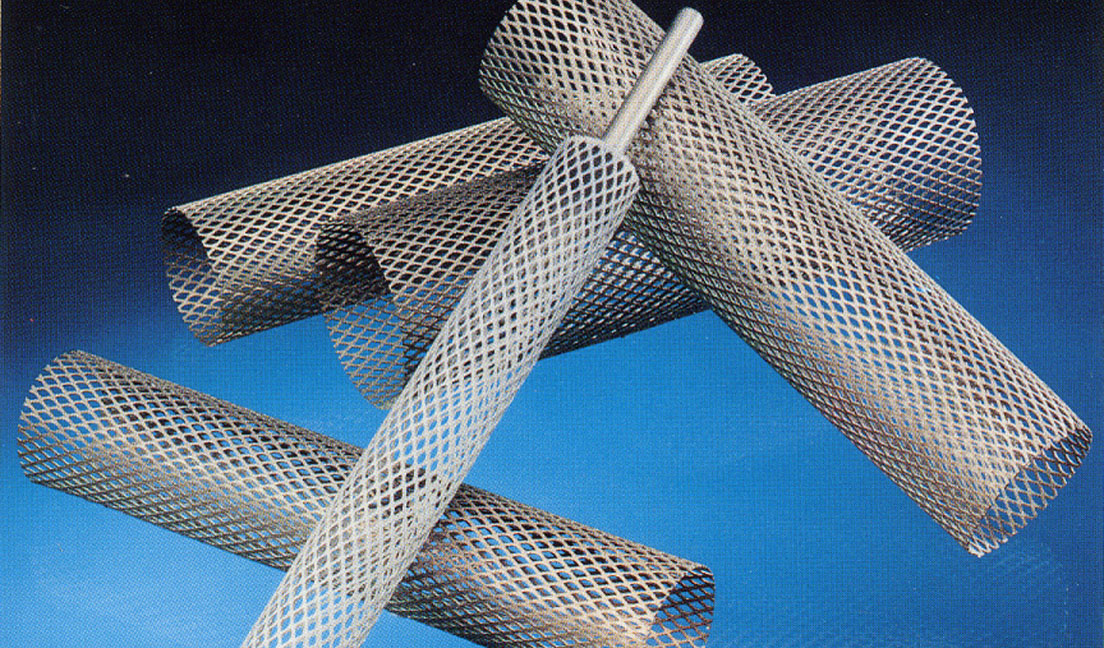

Magneto’s high-quality anodes are leading the market for the wide range of performance benefits they offer operators. They are designed to ensure a long lifespan, stable geometry, with superior strength and the best possible performance – to keep your operations moving. Our anodes are more sustainable than lead or soluble anodes, causing less impact on the environment.

Our in-depth understanding of metal plating applications enables us to work in partnership with our customers and make the best recommendations for their needs. We can customize our anodes to suit the specific size and scope of any project.

Worldwide our anodes are supporting a range of industrial processes, including:

- Electro galvanizing (zinc plating), including steel strip plating (EGL)

- Electro tinning (tin plating), including steel strip plating (ETL)

- Chromium plating (including trivalent chromium), including steel strip plating (ECL)

- Hard chromium plating

- Nickel & zinc-nickel plating

- Precious metal plating, including gold, silver, and platinum

- Electrical contacts via reel-to-reel plating with nickel, tin, silver, and gold

- Copper plating (including reverse pulse plating)

- Metal finishing applications such as electrophoretic deposition (e.g. electrocoating) and aluminium anodising applications