Filter 0

Application

0Market

0

V-Series™ Automatic Screen Filters

State-of-the-art self-cleaning screen filtration technology

Cooling Tower Treatment System

Systems designed to control cooling basin zone filtration to overcome wasted inefficiencies and high power consumption.

Self-Cleaning Intake Suction Screen

Saves time and money by continually removing debris from water

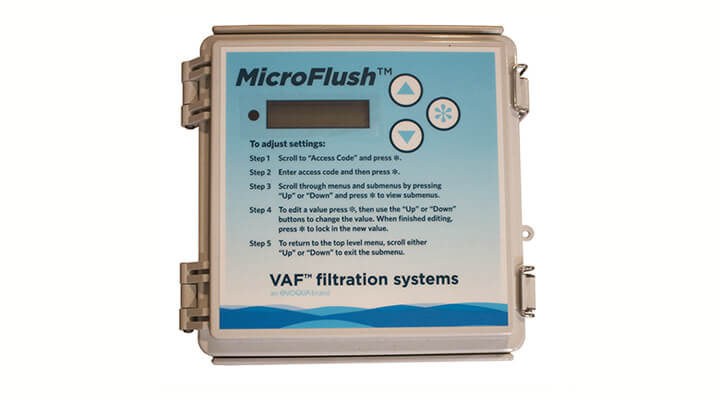

Filtration System Controllers and Valves

Simple and effective control and monitoring for filter systems