This depends on your process. Cloth selection is as much an art as it is a science. Based on our 1,000 years of combined experience and lab testing, we can make an expert recommendation to you. We supply cloths based on criteria you give us and based on sample processing we do in our lab. Should your process change, we recommend that your cloth type be evaluated for suitability.

The following is general information to help you understand cloths and how they work. For detailed questions, call our customer service department at 800.245.3006.

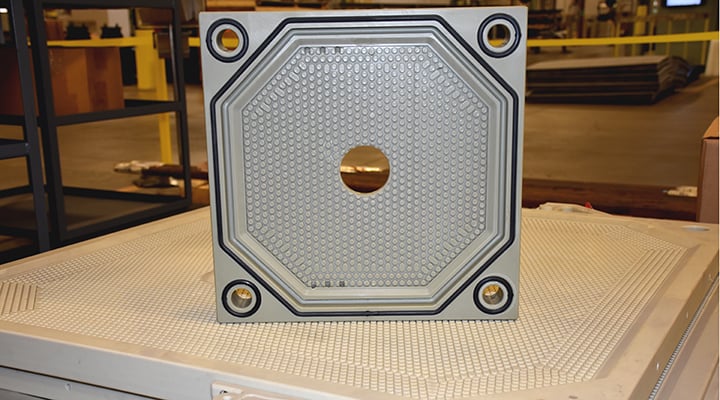

Cloths for non-gasketed plates are hung over the plate, extending from top to bottom, and are held in place by eyelets that fit over the cloth-pins on top of the plates. With the non-gasketed plate, the filter cloth provides the seal between the plates. Leakage will occur during operation even though Evoqua supplies the non-gasketed plate cloths with latex edging. The latex will cut down the wicking action somewhat, but will not eliminate it.

The gasketed plate allows less leakage than the non-gasketed plate due to an O-ring seal around the chamber and filtration ports. The gasketed cloth has a high-density sash cord sewn around the cloth's perimeter that is caulked into a groove on the plate.

The type of cloth used is determined by the type of process or application performed by the filter press, the operating environment, and the performance required by the filtering media (filter cloths).

The filter cloths come in many different materials including polypropylene, polyester, cotton, and other synthetic materials. The cloths are made from monofilament fibers, multifilament fibers, or spun fibers. The smooth surface characteristic of monofilament fibers can help to improve cake release properties. The uniform circumference of monofilaments also enables fabrics to be produced with consistent pore sizes. Multifilament and spun fibers are produced by twisting several smaller diameter monofilament fibers together into a single strand. They are used to produce fabrics that require a very tight weave and fabrics where high flow rates are not critical.

Filter cloths also come in many different styles of fabric weave.

Mesh opening or pore size is also an important consideration when selecting the proper filter cloths for a particular application. The mesh opening or pore size is determined by the number of fibers, size of the fiber, and the type of weave. These factors in turn govern flow rates, particle retention, and the strength of the fabric itself. As shown below, these two fabrics, having the same type of open area, will have similar flow rates, but the fabric on the left will retain finer particles.