Filter 0

Market

0Flow Rate, Minimum: gpm

0Flow Rate, Maximum: gpm

0

Vantage® MICRO FLEX (MFX) Reverse Osmosis Systems

Vantage®MFX Reverse Osmosis (RO) units are pre-engineered and pre-assembled units designed for a variety of industrial and commercial applications. RO membranes typically remove 90-99.9% of suspended and dissolved solids and can remove bacteria and viruses.

Vantage® M41RS (Select)

Vantage® M41 RS Reverse Osmosis (RO) units are pre-engineered and pre-assembled units designed for a variety of industrial and commercial applications. RO membranes typically remove 90-99.9% of suspended and dissolved solids and can remove bacteria and viruses. M41 units are single pass RO systems.

Vantage® M41GP

Vantage® M41 GP Reverse Osmosis (RO) units are pre-engineered and pre-assembled units designed for a variety of industrial and commercial applications. RO membranes typically remove 90-99.9% of suspended and dissolved solids and can remove bacteria and viruses. M41 units are single pass RO systems.

Vantage® M43 Reverse Osmosis Systems

Vantage® M43 Reverse Osmosis (RO) units are pre-engineered and pre-assembled units designed for a variety of industrial and commercial applications. RO membranes typically remove 90-99.9% of suspended and dissolved solids and can remove bacteria and viruses. M43 units are single pass RO systems.

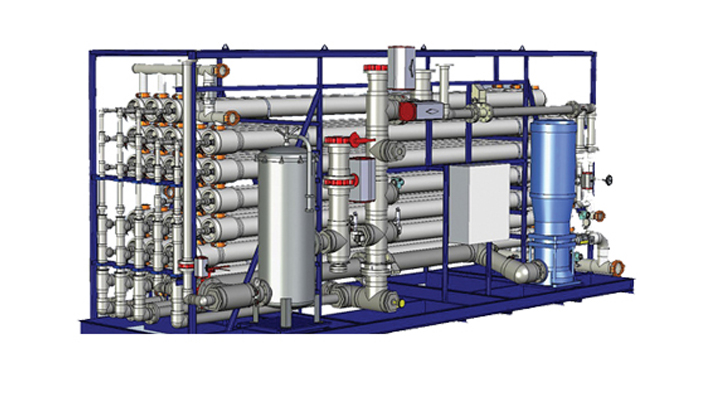

Vantage® M83 Reverse Osmosis Systems

Vantage® M83 Reverse Osmosis (RO) units are pre-engineered and pre-assembled units designed for a variety of industrial and commercial applications. RO membranes typically remove 90-99.9% of suspended and dissolved solids and can remove bacteria and viruses. M83 units are single pass RO systems.

Vantage® M84 Reverse Osmosis Systems

Vantage® M84 Reverse Osmosis (RO) units are pre-engineered and pre-assembled units designed for a variety of industrial and commercial applications. RO membranes typically remove 90-99.9% of suspended and dissolved solids and can remove bacteria and viruses. M84 units are single pass RO systems.

Vantage® M86 Reverse Osmosis Systems

Vantage® M86 Reverse Osmosis (RO) units are pre-engineered and pre-assembled units designed for a variety of industrial and commercial applications. RO membranes typically remove 90-99.9% of suspended and dissolved solids and can remove bacteria and viruses. M86 units are single pass RO systems.

Vantage® M284 Reverse Osmosis Systems

Vantage® M284 Reverse Osmosis (RO) units are pre-engineered and pre-assembled units designed for a variety of industrial and commercial applications. RO membranes typically remove 90-99.9% of suspended and dissolved solids and can remove bacteria and viruses. M284 units are two pass RO systems.

Vantage® M286 Reverse Osmosis Systems

Vantage® M286 Reverse Osmosis (RO) units are pre-engineered and pre-assembled units designed for a variety of industrial and commercial applications. RO membranes typically remove 90-99.9% of suspended and dissolved solids and can remove bacteria and viruses. M286 units are two pass RO systems.

Vantage® Reverse Osmosis Clean-in-Place Systems (CIP Systems)

CIP systems perform regular maintenance cleaning and sanitizing of reverse osmosis and other membrane systems to remove fouling and restore membrane system performance.