Filter 0

Application

0Market

0Flow Rate, Minimum: gpm

0Flow Rate, Maximum: gpm

0

Vanox® AOP System for High Flow TOC Reduction

The AOP high flow system reduces and controls difficult to remove TOC for optimum performance. The advanced oxidation process dynamically responds to incoming TOC variations to maintain a constant effluent.

VANOX® Point-of-Use Filtration System

A compact, ultra clean, point of use filtration system to remove particles from water feeding the critical clean tools used for semiconductor fabrication

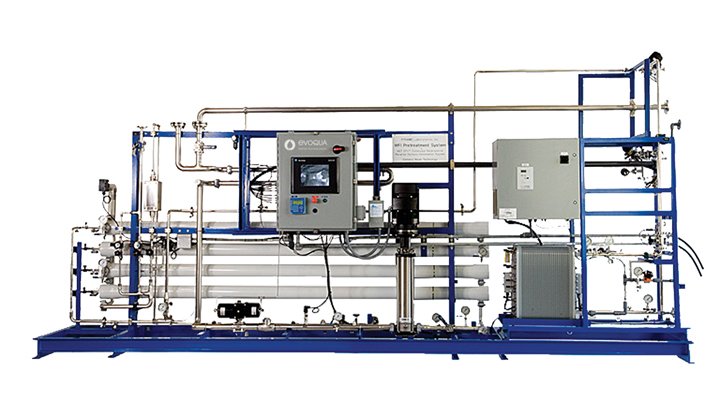

EPV™ Water Purification System

Pre-packaged water systems for biopharmaceutical, cosmetics, laboratory, and medical device manufacturing

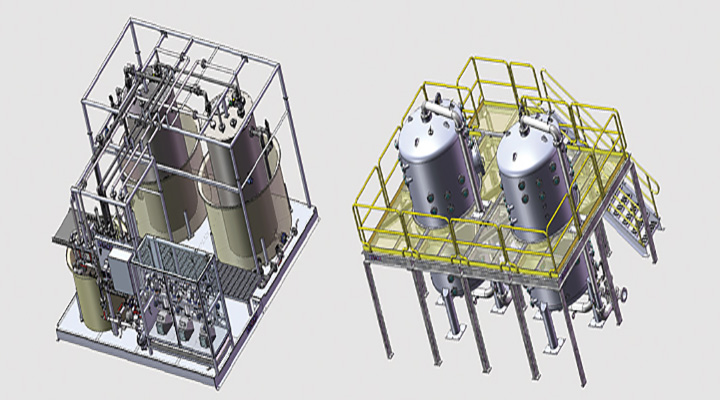

SDRx Storage & Distribution System

Achieve maximum water quality in pharmaceutical applications

Heat Optimized Technology System

The Evoqua HOT recirculating system effectively heat sanitizes carbon towers while reducing water and energy by up to 75% of conventional designs.

CDI-LX®-X

Continuous electrodeionization is a safe, chemical-free way to take RO (reverse osmosis) water to a higher level of purity

CDI-LX®-H

Continuous electrodeionization is a safe, chemical-free way to take RO (reverse osmosis) water to a higher level of purity

DIRS System

Evoqua Water Technologies Deionization Recirculating Systems (DIRS) are economical, pre-packaged, water purification systems producing high purity water.

LDIRS System

The Evoqua Water Technologies LDIRS Series water purification system is a complete, factory assembled, water system designed to deliver up to 3 gpm (11 lpm) or 4 gpm (15 lpm) of deionized water, depending on the application need.

IonRight® System

The IonRight® system combines reverse osmosis and electrodeionization technologies into one cohesive, standard package for reliable, dependable high quality water