Envirex® Sludge Heater and Boilers

See All Digestor ComponentsSludge heaters and biogas boilers for safe, reliable and long-lasting performance

- is the minimum order quantity for this product. Please check quantity and add to cart again.

- No gas conditioning required, burn dirty biogas

- Long-lasting performance and equipment life

- Simple cleaning and maintenance

- Safely prevents combustion gases from entering building space with induced draft system

Sludge heaters and biogas boilers for safe, reliable and long-lasting performance

- No gas conditioning required, burn dirty biogas

- Long-lasting performance and equipment life

- Simple cleaning and maintenance

- Safely prevents combustion gases from entering building space with induced draft system

Description

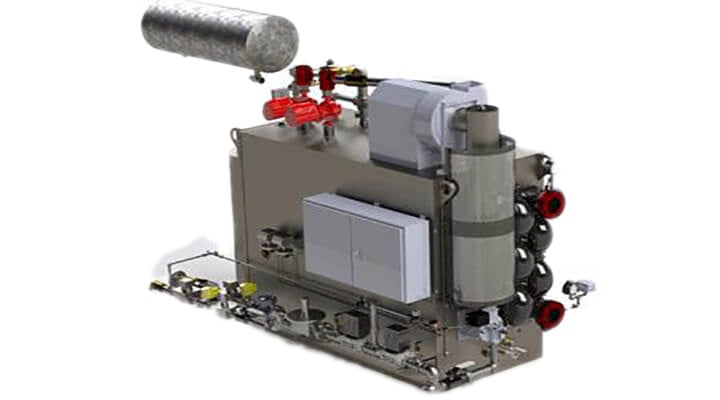

Envirex® combination heaters/heat exchangers and stand-alone biogas boilers are integrally designed to ensure safe and reliable operation for durable, long-lasting performance. Unlike conventional commercial and industrial boilers, the Envriex boiler is designed speciifcally for burning dirty biogas. These are the next generation of the well-known PFT®/and Envirex sludge heating products, for which Evoqua is the OEM.

The flame safeguard system and induced draft fan eliminates the possibility of dangerous gas leaks. In addition, the induced draft design permits the burner to operate at a lower gas pressure, eliminating the need for gas booster pumps and optimizing the use of free digester gas. The rear return section, known as the water back, is guaranteed to last the life of the boiler unlike conventional return sections that utilize refractory, which require frequent replacement.

Advanced options are available for maximum efficiency and low emissions requirements. A state of the art Honeywell combustion control system provides 24/7 monitoring and control to ensure maximum utilization of digester gas. A low emissions Honeywell/Maxon burner is also available to meet strict emissions requirements.

Envirex tube-in-tube heat exchangers are also available for applications where a facility already has a hot water source or is using a separate hot water boiler. The proven grooved piping system provides efficient heating or cooling of sludge with large return elbows to prevent clogging

Features

Features

- Designed and certified to ASME IV - Heating boilers

- Flame safeguard system

- Durable swaged firetube construction

- Induced draft fan

- Automated controls

- Remote monitoring controls available

- Fully assembled and tested skid

- Reserve boiler capacity avilable for process or building heat

Options Available:

- Combination heater & heat exchanger

- Combination heater & heat exchanger w/ resever boiler capacity

- Stand-alone boiler (no heat exchanger)

Documentation

- Envirex Heater / Heat Exchanger902.2 KB

- Digester Heating Solutions812.8 KB